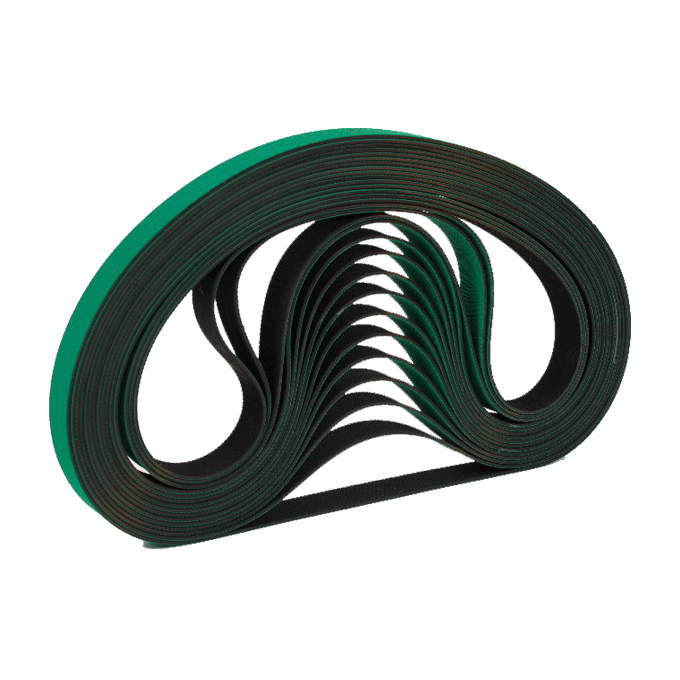

PVC Roller Sleeve

PVC roller sleeves are cylindrical in shape and typically have a smooth or curved surface with a slightly glossy appearance. They come in different sizes and thicknesses to fit various roller diameters. PVC roller sleeves are generally durable and abrasion-resistant, making them popular for various industrial applications. They can provide good traction, grip, and resistance to chemicals, oils, and UV radiation. PVC roller sleeves are also lightweight and flexible, which can help reduce wear and tear on conveyor systems and other equipment.

What is a PVC sleeve?

PVC is a thermoplastic material with a reinforced structure. It is quite rigid, but has a certain degree of flexibility. PVC sleeves are therefore generally used to protect and insulate cables.

When there are complex electrical installations, it is normal that the space ends up feeling a little short. Consequently. Limes run the risk of rubbing against each other, or touching other important components. Since no one wants a short circuit, PVC sleeves are used.

Features of the PVC sleeve

Reducing the risk of accidents is not only important, but mandatory. This alternative, besides being inexpensive, has several features that make it a great solution.

●PVC sleeves are extremely versatile, as they can be used in a huge range of situations.

●Despite being a rigid material, PVC can be molded using heat. This makes it possible to organize our electrical systems as we wish.

●PVC has no smell or taste. This is not the case with polyurethane, for example, but what does this mean? There will be systems that require more purity. Perhaps you are working with a drinking water plant and there should be no flavors left in the liquid.

●PVC sleeves can protect against weather, abrasive chemicals, chafing and extreme heat. It will keep the cables (or whatever is inside) completely insulated from danger.

PVC Sleeve Applications

As mentioned above, PVC sleeves have a wide range of applications. Basically, they can be used wherever there are electrical cables that need to be kept insulated. In complex electrical systems, it is common to find quite a few sleeves of this type to separate some assemblies from others.

It is also common to see it in concrete and/or poured concrete constructions. In a nutshell, PVC is placed where the wiring will run in the future. Cement is then poured over the sleeve, leaving a clean and safe pathway for the cables.

The marine and automotive industries use PVC sleeves to organize their engine wiring and create a secure system. Also, whenever cable bundling is needed, a PVC sleeve is the best option.

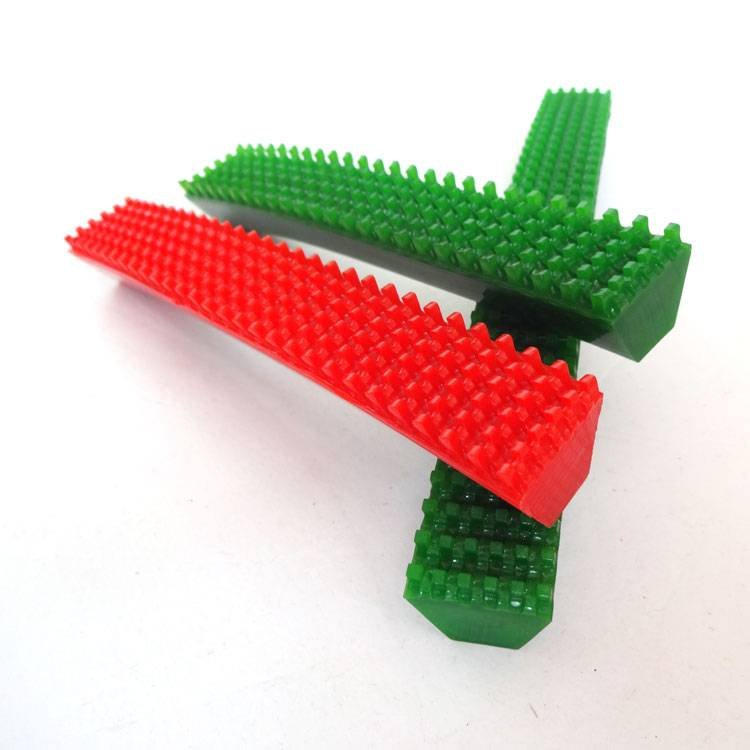

| ltem Name | Specification(mm) | Color | Thickness | Surface | Material Type |

| PVC Sleeve | 20×2.5

25×2.5 27×2.5 30×2.5 32×2.5 35×2.5 38×2.5 40×2.5 42×2.5 45×2.5 50×2.5 55×2.5 60×2.5 65×2.5 70×2.5 75×2.5

|

Red/ Black | 2mm 2.5mm 2.75mm | Smooth/Curve | Hard/Soft High temperature resistant |

| Other size and thickness can be customized | |||||

All sizes/colors/hardness/etc. can be customize according to your request.

Related Posts