When considering materials for industrial, automotive, or engineering projects, one question often arises: what is thermoplastic polyurethane (TPU) and why is it so widely used? TPU is a versatile polymer that combines the processing ease of plastics with the elasticity of rubber. Its unique properties make it ideal for applications requiring durability, flexibility, and chemical resistance. Choosing the right type of TPU is crucial to ensure optimal performance, long-term reliability, and cost-effectiveness.

In this article, we will explain what is thermoplastic polyurethane, explore its key properties, and provide practical guidance on choosing the right TPU for your specific project needs.

Understanding Thermoplastic Polyurethane (TPU)

What is thermoplastic polyurethane? TPU is a high-performance polymer made from segmented block copolymers. Its thermoplastic nature allows it to be melted, molded, and reshaped multiple times without losing physical properties. This capability enables manufacturers to create custom components efficiently.

TPU combines the strength and rigidity of plastic with the elasticity of rubber. Unlike traditional materials such as PVC, rubber, or standard plastics, TPU provides superior abrasion resistance, chemical stability, and long-term durability under mechanical stress. Understanding what is thermoplastic polyurethane helps engineers and product designers select the most suitable material for high-performance applications.

Key Factors to Consider When Choosing TPU

- Hardness and Flexibility

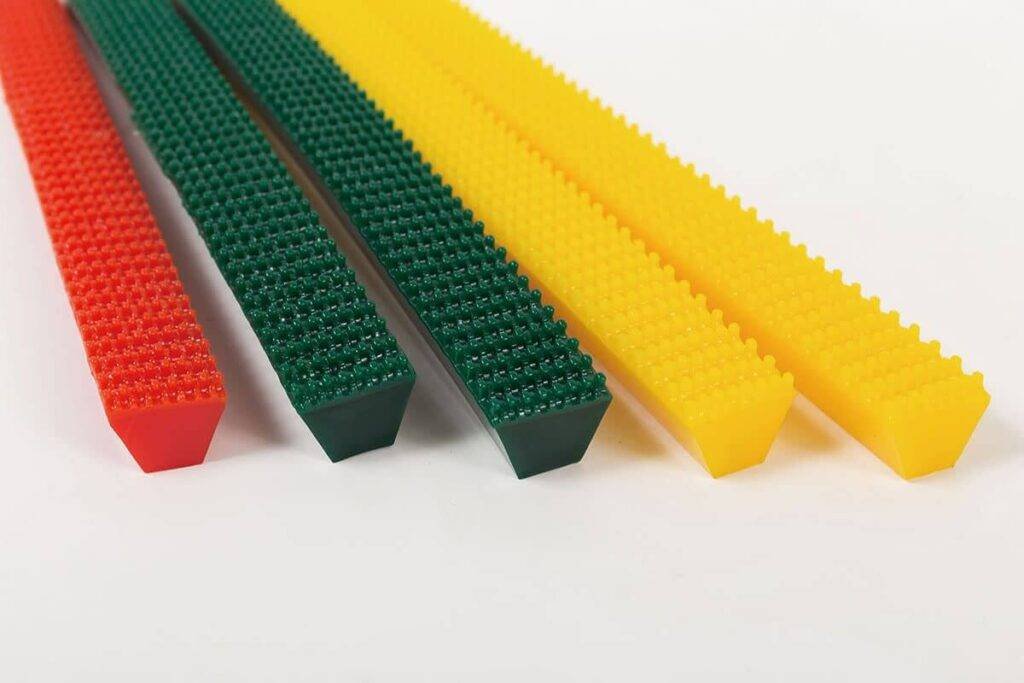

Knowing what is thermoplastic polyurethane allows you to choose the correct hardness level. TPU is available in a wide range of hardness grades, measured on the Shore A or Shore D scale. Softer TPU is ideal for cushioning, vibration damping, and flexible applications, while harder TPU provides structural integrity for heavy-duty or high-wear areas. Selecting the appropriate hardness ensures components perform effectively under operational conditions. - Thickness and Dimensions

The thickness of TPU sheets, tubing, or molded components affects durability and flexibility. Thicker materials offer greater wear resistance, while thinner materials provide adaptability for complex or curved surfaces. Choosing the correct dimensions is essential for both performance and cost-efficiency. - Chemical and Temperature Resistance

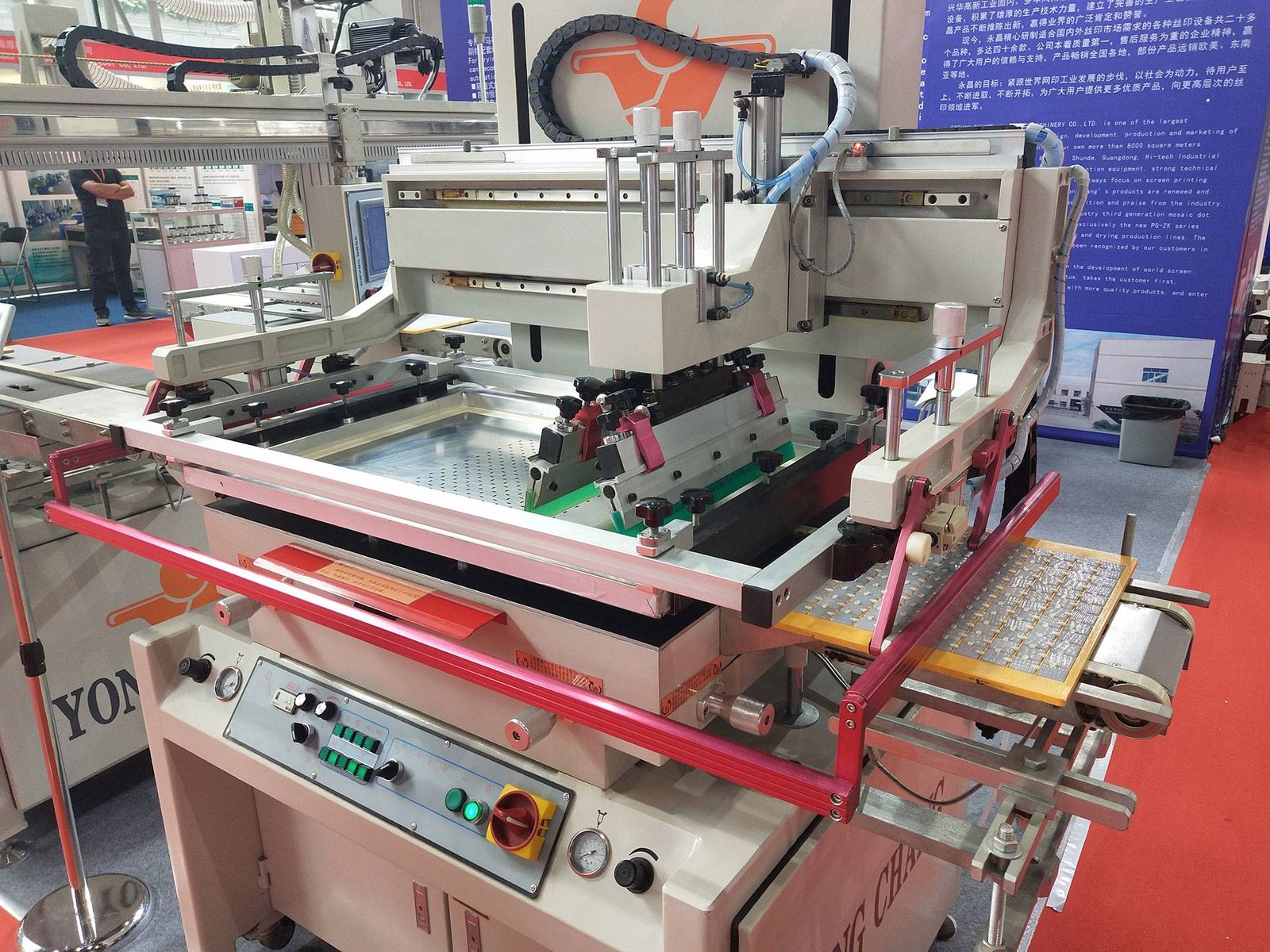

Different applications expose TPU to oils, solvents, acids, and temperature extremes. Choosing a TPU material with suitable chemical and temperature resistance ensures components maintain their integrity and avoid premature failure. Knowing what is thermoplastic polyurethane helps in evaluating chemical compatibility for industrial, medical, and automotive uses. - Processing and Fabrication Requirements

TPU can be processed through injection molding, extrusion, or compression molding. Understanding what is thermoplastic polyurethane and its processing capabilities helps manufacturers select the best type for specific fabrication methods. - Durability and Wear Resistance

High-wear applications demand TPU with excellent abrasion resistance. Selecting the right grade extends component life, reduces maintenance, and enhances overall system efficiency.

Applications-Based Selection

Automotive Components: TPU is used for seals, hoses, bushings, and vibration-damping elements. Its flexibility and wear resistance ensure reliable performance under dynamic conditions.

Industrial Machinery: In heavy-duty equipment, TPU provides protective pads, guide rails, and conveyor components. Its durability reduces maintenance and prevents premature wear.

Medical and Food Processing: TPU can be formulated to meet safety and hygiene standards. It is ideal for tubing, protective covers, and other applications requiring chemical resistance and biocompatibility.

Electronics and Electrical Applications: TPU’s chemical resistance, insulation properties, and vibration-damping characteristics make it suitable for cable sheaths, protective coatings, and precision components.

By evaluating the specific demands of each application, you can select a TPU type that ensures performance, reliability, and cost-effectiveness.

Comparison of TPU Types

Different TPU types are optimized for specific properties:

| TPU Type | Hardness | Flexibility | Chemical Resistance | Ideal Applications |

|---|---|---|---|---|

| Soft TPU | Low | High | Moderate | Cushioning, vibration damping |

| Hard TPU | High | Moderate | High | Heavy-duty machinery, wear parts |

| Transparent TPU | Moderate | High | Moderate | Inspection windows, protective covers |

| Chemical-Resistant TPU | Moderate-High | Moderate | High | Industrial chemicals, medical |

Using this comparison helps guide the selection of the most appropriate TPU for your project.

Tips for Selecting the Right TPU Supplier

Choosing a reliable supplier ensures the quality and performance of thermoplastic polyurethane. Look for suppliers with:

- Proven industry experience and technical expertise.

- Customization capabilities for specific shapes, hardness, and dimensions.

- Quality certifications and consistent production standards.

- Global service and technical support for industrial applications.

Working with a trusted supplier like PENGDE ensures that you receive high-quality, durable, and customizable TPU products for your projects.

Conclusion

Understanding what is thermoplastic polyurethane and how to select the right type is critical for industrial, automotive, and engineering applications. By considering hardness, thickness, chemical resistance, fabrication requirements, and durability, you can ensure that TPU components perform reliably, reduce maintenance costs, and enhance project efficiency.

For premium, customizable, and high-performance thermoplastic polyurethane products, trust PENGDE. With over 15 years of experience in PU plastic production and a strong global reputation, PENGDE provides expert solutions to meet your project’s specific needs. Upgrade your components today with high-quality TPU and achieve long-lasting, reliable performance.

Email: pengde2@pengde-pu.com

Company: PENGDE NEW MATERIAL TECHNOLOGY CO., LTD