In modern industrial automation, tpu conveyor belt is widely used for its wear resistance, flexibility, high hygiene standards, and extensive customization options. It finds applications in food processing, logistics sorting, electronics manufacturing, packaging, and pharmaceutical industries.

However, many companies only focus on thickness or color when selecting conveyor belts, overlooking how different operating conditions can significantly impact performance.

This guide is designed to help overseas engineers, equipment manufacturers, and industrial buyers choose the most suitable tpu conveyor belt solutions. Based on real manufacturing experience, we provide actionable guidance for customizing belts according to industry-specific requirements.

1. Why TPU Conveyor Belts Require Customization

Every factory has unique production environments, conveyed materials, equipment structures, and temperature or humidity conditions. Standard belts often cannot ensure long-term stable operation. Customized tpu conveyor belts have become the mainstream choice in European and American markets for several key reasons:

- Adapt to Complex Operating Conditions and Improve Stability

- Logistics sorting lines require high wear resistance and high-speed stability.

- Food processing lines need food-grade, easy-to-clean, and oil-resistant materials.

- Electronics industry requires anti-static and dust-free materials.

- Pharmaceutical packaging lines demand chemical resistance and high hygiene standards.

- Extend Service Life and Reduce Maintenance Costs

Custom specifications reduce common issues like belt misalignment, breakage, and surface wear, significantly minimizing downtime and maintenance expenses. - Enhance Equipment Efficiency and Conveying Accuracy

Belt hardness, surface texture, and thickness directly affect conveying accuracy, noise levels, and operational stability. - Meet OEM and Brand Differentiation Needs

Custom colors, textures, and joint types allow OEMs to create unique conveyor solutions for their production lines.

2. Key Customizable Parameters of TPU Conveyor Belts

Based on long-term overseas industrial procurement experience, customization typically focuses on the following parameters:

| Parameter | Options / Range | Industrial Considerations |

|---|---|---|

| Thickness | 0.8–3.0 mm | 0.8–1.2 mm: electronics, pharmaceuticals, light loads; 1.5–2.0 mm: food, packaging, logistics; 2.0–3.0 mm: heavy-duty or high-wear lines |

| Hardness (Shore A) | 70–98A | 70–80A: soft, low-noise, light loads; 85–90A: balanced wear and flexibility; 95–98A: high wear and heavy load |

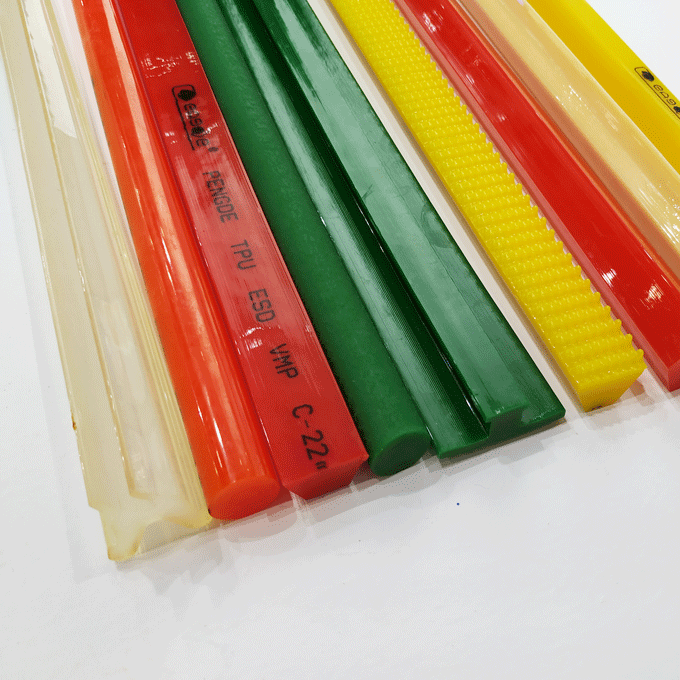

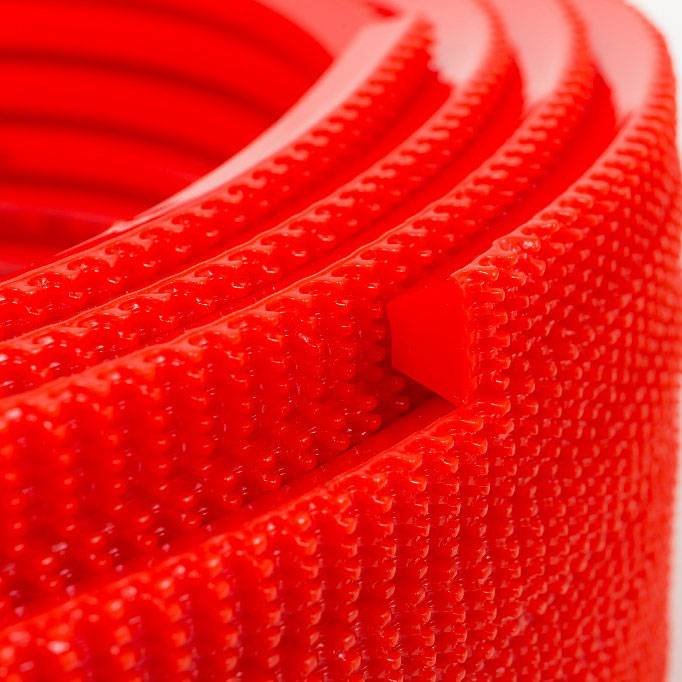

| Surface Texture | Glossy, Matt, Diamond, Grass | Affects friction, anti-slip, and noise; choose per industry |

| Color | White, Blue, Transparent, Black | White: food-grade; Blue: food processing visual management; Transparent: electronics; Black: general industrial |

| Tensile Strength | 30–50 MPa | Ensures long-term performance under load |

| Tear Resistance | 70–120 kN/m | Key for high-stress or sharp-edged materials |

| Abrasion Resistance | 25–40 mm³ (DIN Abrasion) | Determines lifespan under high-wear conditions |

| Temperature Range | -20°C to +80°C | Short-term tolerance up to 100°C |

| Joint & Edge Options | Hot welding, Mechanical buckle, Reinforced edges, V-guide | Critical for belt stability, alignment, and durability |

3. Industry-Specific Custom TPU Conveyor Belt Solutions

The following applications are based on real overseas projects and factory cases from PENGDE.

| Industry | Key Requirements | Recommended Customization |

|---|---|---|

| Food Processing | Food-grade, oil-resistant, easy to clean | Thickness: 1.5–2.0 mm; Hardness: 85–90A; Surface: Glossy or Matt; Temp: -20°C to +80°C; Color: Blue |

| Logistics & Sorting | High wear resistance, stable at high speed | Thickness: 1.8–2.5 mm; Hardness: 90–95A; Surface: Diamond or Grass; Joint: Hot weld + V-guide |

| Electronics Manufacturing | Anti-static, low noise, high precision | Thickness: 1.0–1.5 mm; Hardness: 80–85A; Surface: Glossy; Color: Transparent/White |

| Pharmaceutical | High hygiene, chemical-resistant | Thickness: 1.0–1.5 mm; Hardness: 80–85A; Surface: Glossy; Color: White |

| Packaging & Printing | Wear-resistant, oil/ink-resistant | Thickness: 1.5–2.5 mm; Hardness: 85–95A; Surface: Matt or Diamond |

4. How to Select the Right TPU Conveyor Belt for Your Factory

Before choosing custom parameters, evaluate your production requirements:

- Conveyed Material Characteristics

- Light vs heavy loads

- Sharp edges

- Oil, grease, or dust presence

- Equipment Speed and Tension

- High-speed lines require higher tensile strength and stability

- Working Environment

- High/low temperatures

- High humidity

- Food-grade requirements

- Cleaning Methods

- Strong alkaline or alcohol-based cleaners may affect material choice

- Service Life and Maintenance Frequency

- Food industry: shorter lifespan

- Logistics: higher wear

- Electronics: strict stability requirements

5. Why Choose PENGDE for TPU Conveyor Belt Customization

- Real Manufacturing Capability, Not a Trading Company

- PENGDE, established in 2008, has full in-house production from raw material formulation to extrusion and casting.

- Industrial TPU Belt Expertise

- Customizable parameters: thickness, hardness, surface texture, transparency, color, abrasion resistance, anti-static properties.

- Experience Across Multiple Overseas Industries

- Long-term partners in Europe, North America, Southeast Asia, and Latin America, including food factories, ceramic plants, and logistics equipment manufacturers.

- One-Stop Custom Solution

- Requirement evaluation → Material formula selection → Drawing-based processing → Mass production → Global export

- Verified Quality Control

- All belts undergo tensile, tear, abrasion, and temperature tests

- Food-grade material certification available (third-party reports can be provided)

6. Conclusion

Whether in food processing, logistics, electronics, or industrial equipment manufacturing, customizing tpu conveyor belts can significantly improve production efficiency and equipment stability. Choosing the right parameters reduces wear, minimizes downtime, and extends service life, making it a cost-effective investment for industrial enterprises.

For professional TPU conveyor belt customization, contact pengde2@pengde-pu.com for technical support and engineering advice.