Polyurethane (PU) has become an essential material in modern industrial manufacturing due to its high elasticity, excellent wear resistance, oil resistance, and chemical stability. It is widely used in automotive parts, electronics, ceramics, mechanical components, and conveyor belts. Understanding how is polyurethane produced is crucial for overseas buyers, equipment manufacturers, and engineers. It not only helps in selecting the right products but also ensures reliability and long-term stability in industrial operations. This article provides a comprehensive overview of PU production, including raw materials, manufacturing processes, quality control, and typical applications.

1. What is Polyurethane (PU)?

Polyurethane is a polymer formed through the chemical reaction between isocyanates and polyols. Depending on processing methods and applications, it can be classified into two main types:

- Thermoplastic Polyurethane (TPU)

- Can be extruded, injection molded, or processed into films, belts, and sheets

- Offers high wear resistance, elasticity, and can be transparent or colored

- Cast Polyurethane (PU Casting)

- Suitable for high-strength components, cushioning parts, and mechanical supports

- Provides excellent wear resistance and impact protection

The core properties of PU—elasticity, wear resistance, and chemical stability—make it highly valuable across industrial applications.

2. Raw Materials for Polyurethane Production

The quality of raw materials directly affects the performance of the final PU product. Key materials include:

| Material | Function | Notes |

|---|---|---|

| Isocyanates (MDI/TDI) | React with polyols to form PU backbone | Determines hardness and mechanical strength |

| Polyether / Polyester Polyols | Provide flexibility and elasticity | Polyether or polyester chosen based on application |

| Catalysts | Accelerate chemical reaction | Controls curing speed |

| Blowing Agents | Used for foamed PU | For sponge or foam applications |

| Toughening Agents | Improve toughness and wear resistance | Essential for industrial-grade PU |

| Pigments / Fillers | Coloring or enhanced performance | Can be customized based on client needs |

Overseas clients often prioritize material consistency and batch-to-batch reliability to ensure stable mechanical performance and durability.

3. Polyurethane Production Process

Mixing & Prepolymer Formation

Polyols and isocyanates are mixed in precise ratios to form a prepolymer.

- Accurate formula control ensures consistent hardness and elasticity

- Additives are incorporated at this stage to enhance wear resistance, oil resistance, or chemical stability

Casting & Extrusion

- Cast PU: Ideal for rods, cushioning parts, and mechanical components

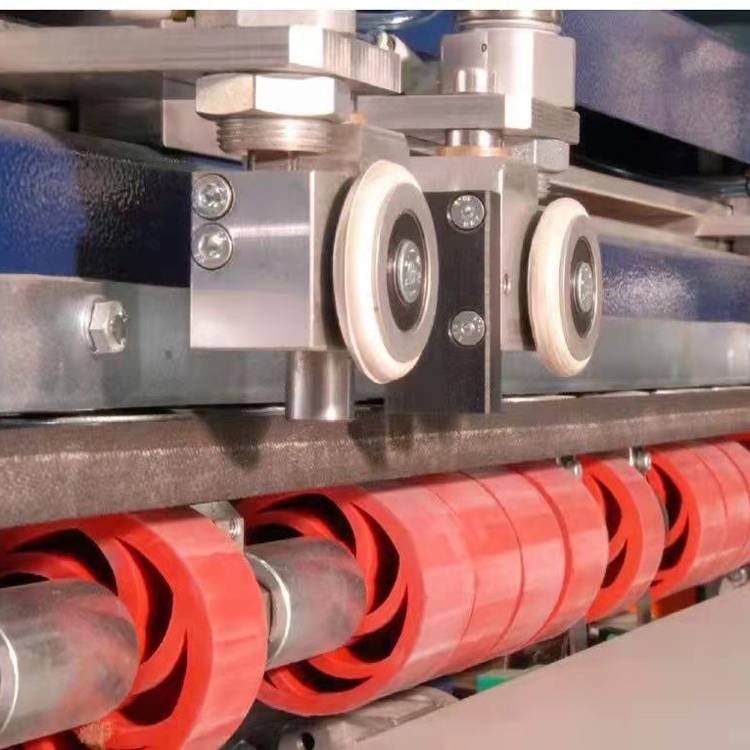

- TPU Extrusion: Used for conveyor belts, sheets, and films

- Temperature, pressure, and cooling rate directly affect the final product quality

Curing & Post-processing

- Curing methods include heat curing and room temperature curing

- Post-processing such as cutting, polishing, and surface treatment improves dimensional accuracy and mechanical performance

Quality Inspection & Testing

| Test Type | Typical Range | Purpose |

|---|---|---|

| Hardness | Shore A / D | Ensure design requirements are met |

| Tensile Strength | 25–50 MPa | Verify load-bearing capacity |

| Tear Strength | 60–150 kN/m | Ensure durability |

| Abrasion Resistance | 25–40 mm³ | Extend service life |

| Oil & Chemical Resistance | Excellent | Suitable for industrial environments |

| Temperature Range | -30°C to +80°C | Confirm environmental adaptability |

These tests ensure that each batch meets client requirements for both mechanical and chemical performance.

4. How Different PU Types Affect Applications

| PU Type | Typical Applications | Key Performance Benefits |

|---|---|---|

| Cast PU | Industrial rods, cushioning parts, wear-resistant components | High wear resistance, strength, impact resistance |

| TPU | Conveyor belts, sheets, films | High elasticity, wear resistance, transparent or color-customizable |

Selecting the right type and parameters for each application ensures stable equipment operation and longer service life.

5. Key Considerations When Purchasing Polyurethane

- Material quality and supply stability

- Factory production capacity and customization capabilities

- Certifications and third-party testing reports

- Customizable formulations and properties (hardness, color, dimensions, tolerances)

Working with a reliable manufacturer reduces downtime, minimizes maintenance costs, and ensures batch-to-batch consistency.

6. Why Choose PENGDE

- 15+ years of PU manufacturing experience: Specializing in PU customization and industrial parts production

- In-house formulas and precision equipment: Ensures stable dimensions and performance

- Proven overseas client experience: Long-term cooperation with ceramic, electronics, machinery, and food industry factories in Europe, Southeast Asia, and the Americas

- Full customization capabilities: Hardness, length, color, formulation, and drawings can all be tailored

- Strict quality control: Tensile, tear, abrasion, and temperature tests, with optional third-party reports

PENGDE’s professional team provides end-to-end technical support from raw material selection to finished PU products.

7. Conclusion

Understanding how is polyurethane produced is essential for overseas buyers, OEM manufacturers, and industrial engineers. By knowing the raw materials, manufacturing process, and testing methods, companies can select the most suitable PU products to improve equipment efficiency and service life. Choosing PU products from PENGDE ensures high performance, reliable specifications, and professional engineering support.

For samples, specifications, or custom PU solutions, please contact the PENGDE technical team. Email: pengde2@pengde-pu.com