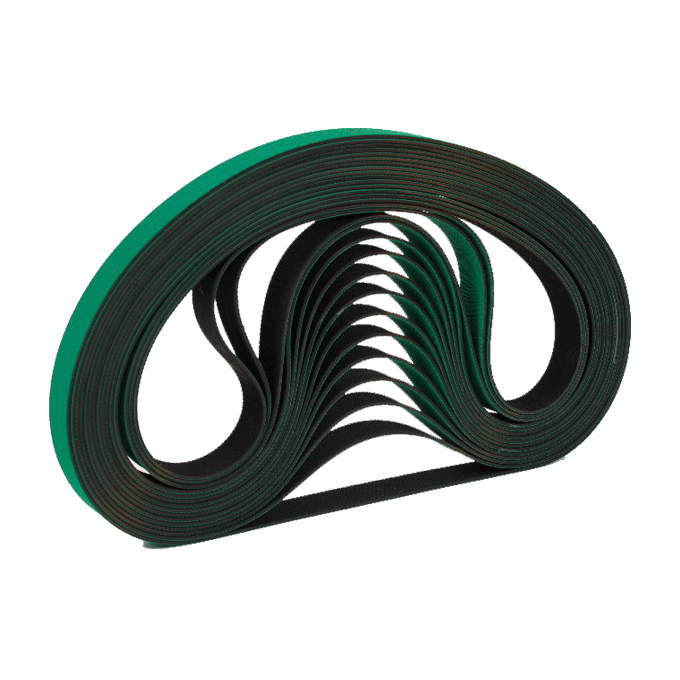

Screen Printing Squeegee

Screen Printing Squeegee

Screen printing squeegees are essential tools used to transfer ink evenly through mesh screens onto substrates with high precision and consistency. Our polyurethane screen printing squeegees are manufactured from premium PU elastomer, delivering superior durability, flexibility, and ink control compared to traditional rubber blades.

Specifications

- Material: High-performance polyurethane (PU) elastomer

- Blade Type: Screen printing squeegee blade / strip

- Hardness Options: Soft, medium, hard (multiple Shore A grades)

- Width: Customizable

- Thickness: Customizable

- Length: Custom cut or standard lengths

- Edge Profile: Square, beveled, rounded, or custom shapes

- Color Options: Standard or customized

Key Features & Performance Advantages

- Superior Ink Transfer Control

Provides clean, consistent prints with sharp image definition - Excellent Wear Resistance

Maintains blade shape longer than rubber squeegees - High Elastic Recovery

Returns quickly to original form for uniform pressure distribution - Chemical & Solvent Resistant

Suitable for various inks and cleaning solutions - Multiple Hardness Options

Soft for delicate prints, hard for high-detail or heavy ink deposits - Precision Cut Edges

Ensures smooth ink flow and consistent results

Typical Applications

- Textile and garment printing

- Ceramic tile and decoration printing

- Glass and bottle printing

- Electronic circuit and PCB printing

- Packaging and label printing

- Graphic and industrial screen printing

Customization & OEM Services

- Custom blade lengths, widths, and thicknesses

- Hardness selection based on printing requirements

- Special edge profiles for different ink flows

- OEM branding and packaging available

FAQ

Q1: Why are PU squeegees better than rubber ones?

PU squeegees offer higher wear resistance, better edge retention, and longer service life, resulting in more consistent printing quality.

Q2: How do I choose the right hardness for screen printing?

Soft blades are suitable for heavy ink deposits and uneven surfaces, medium hardness for general printing, and hard blades for fine details and sharp edges.

Q3: Can the squeegee blades be customized?

Yes, sizes, hardness levels, edge shapes, and colors can be fully customized.

Q4: Are PU squeegees resistant to solvents and inks?

Yes, polyurethane performs well with most screen printing inks and cleaning chemicals.

Q5: What is the typical lifespan of a PU screen printing squeegee?

PU blades generally last much longer than rubber squeegees, especially in high-volume production environments.