In today’s fast-paced industrial landscape, the demand for customized solutions is growing. TPU (Thermoplastic Polyurethane) belts are no exception, offering a versatile and durable option for industries with specific performance needs. Unlike traditional conveyor belts, custom TPU belts can be tailored to meet the unique challenges faced by various industries, ensuring optimized efficiency, extended lifespan, and enhanced safety. Whether it’s food processing, automotive manufacturing, or packaging, custom TPU belts provide industry-specific advantages that help companies streamline operations and reduce costs.

In this article, we will explore the various industries that benefit from custom TPU belt solutions and highlight their key applications and advantages.

What Are Custom TPU Belts?

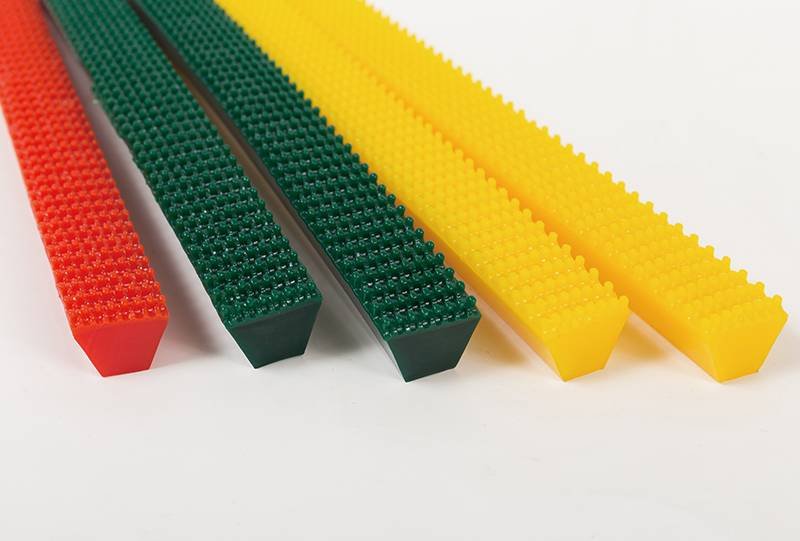

Custom TPU belts are made from thermoplastic polyurethane, a material known for its exceptional durability, flexibility, and chemical resistance. These belts are used in a wide range of applications, where standard conveyor belts may fall short. By customizing the width, thickness, surface texture, and composition, TPU belts can be engineered to meet the specific needs of different industries.

Advantages of Custom TPU Belts

1. Tailored Performance for Unique Requirements

One of the main advantages of custom TPU belts is the ability to tailor them to suit the specific operational conditions of an industry. Whether it’s adjusting the flexibility, strength, or abrasion resistance, custom TPU belts are designed to perform optimally in the harshest environments. For industries that require specific materials, such as food-safe TPU belts or oil-resistant TPU belts, customization ensures that the belts meet all necessary standards.

2. Improved Durability and Longevity

The customized nature of TPU belts means they can be made to withstand specific challenges such as extreme temperatures, heavy loads, or abrasion. Custom TPU belts are engineered for maximum durability, resulting in a longer service life and less frequent maintenance, which translates to cost savings for industries with high-volume operations.

3. Enhanced Hygiene and Safety

In industries like food processing, where hygiene and safety are critical, custom TPU belts offer tailored solutions that comply with FDA and EU regulations. These belts can be made with non-porous surfaces, ensuring that they don’t harbor bacteria or contaminants, making them a safer option for industries that deal with food handling, pharmaceuticals, or chemicals.

4. Flexibility and Adaptability

Custom TPU belts are highly adaptable to different machinery and production environments. Whether it’s a curved conveyor, inclined conveyor, or multi-directional system, TPU belts can be customized in terms of flexibility and design to meet specific needs, ensuring smooth and efficient material handling.

Industries Benefiting from Custom TPU Belt Solutions

1. Food Processing and Packaging

In the food processing and packaging industry, cleanliness is paramount. Custom TPU belts are tailored to be non-porous, easy to clean, and resistant to oils, fats, and chemicals commonly used in food production. These belts can be designed to handle fragile food products, such as fruits and baked goods, without damaging them. Additionally, the smooth surface of custom TPU belts ensures that they meet stringent food safety regulations, including FDA and HACCP compliance.

Applications in Food Processing:

- Bakery lines: Moving dough, bread, and pastries with minimal sticking.

- Meat and poultry processing: Resistant to fats, oils, and high temperatures.

- Beverage packaging: Transporting bottles and cans in high-speed packaging lines.

2. Automotive Manufacturing

In the automotive manufacturing sector, custom TPU belts are used in high-demand applications, including assembly lines, parts handling, and paint booths. The abrasion resistance and oil resistance of TPU belts make them ideal for environments where components need to be moved with high precision and in extreme conditions. Custom TPU belts can be designed to accommodate heavy-duty loads while maintaining high performance in the assembly process.

Applications in Automotive Manufacturing:

- Assembly line conveyors: Moving heavy automotive parts such as engines, doors, and chassis.

- Paint booths: Transporting parts while resisting paint and chemicals.

- Parts sorting and inspection: Ensuring smooth and precise movement during sorting stages.

3. Pharmaceutical and Medical Industries

In the pharmaceutical and medical industries, cleanliness and regulatory compliance are non-negotiable. Custom TPU belts are designed to meet the high standards required in these fields, offering resistance to harsh chemicals and ease of cleaning. With FDA-compliant options, custom TPU belts are ideal for drug manufacturing, packaging, and transporting sensitive materials like vials, syringes, and other medical components.

Applications in Pharmaceutical and Medical Industries:

- Conveyor belts in drug production: Safe transportation of pharmaceutical ingredients and finished products.

- Medical device assembly: Handling delicate medical parts without contamination.

- Packaging lines: Transporting medical supplies with minimal risk of contamination.

4. Textile and Apparel Manufacturing

In textile and apparel manufacturing, custom TPU belts provide solutions that are both abrasion-resistant and flexible enough to handle materials such as fabric, yarn, and garments. TPU belts are customizable to move delicate textiles without causing damage or friction, reducing the wear and tear on materials during the manufacturing process. Additionally, they can be designed to handle high speeds and continuous operations, essential for efficient production lines.

Applications in Textile and Apparel Manufacturing:

- Fabric handling: Moving textiles without causing snags or abrasions.

- Yarn transport: Ensuring smooth transport of fibers in high-speed machinery.

- Garment assembly: Smooth movement of finished garments without creasing or damage.

5. Packaging and Logistics

In the packaging and logistics industry, custom TPU belts are used to transport goods through highly automated systems. The flexibility and high load-bearing capacity of TPU belts ensure that they can carry heavy packages while maintaining smooth and precise operation. Custom TPU belts can be designed for specific packaging line requirements, including product alignment, labeling, and sorting.

Applications in Packaging and Logistics:

- Packaging lines: Transporting products through automated packaging systems.

- Sorting systems: Moving packages for efficient sorting in distribution centers.

- Material handling: Moving heavy packages or fragile goods with minimal risk of damage.

6. Mining and Heavy Industry

For mining and heavy industries, custom TPU belts are engineered to withstand extreme conditions, such as abrasion, heavy loads, and extreme temperatures. These belts are crucial for transporting materials like coal, minerals, and aggregates in mining operations. Custom TPU belts offer greater strength and resistance compared to traditional materials, making them an ideal solution for rugged environments.

Applications in Mining and Heavy Industry:

- Bulk material handling: Transporting aggregates, coal, and minerals.

- Heavy-duty conveyors: Moving large and heavy items in mining and construction sites.

- Dust and debris management: Preventing damage in environments with high dust exposure.

Conclusion

Custom TPU belts are a game-changer for industries that require tailored solutions to meet specific operational challenges. From food processing to automotive manufacturing and pharmaceutical industries, TPU belts provide improved durability, hygiene, and safety. Their adaptability to different environments and ability to withstand extreme conditions make them indispensable in modern industrial applications.

At PENGDE NEW MATERIAL TECHNOLOGY CO., LTD, we specialize in providing custom TPU belt solutions for a variety of industries. Our belts are engineered for maximum performance, durability, and compliance with industry regulations, helping your business optimize its operations and reduce costs. For more information or to discuss your specific needs, please contact us at pengde2@pengde-pu.com.