Customized Polyurethane (PU) Solution

From formulation and hardness to tooling and mass production — we provide one-stop PU customization that meets every requirement for performance, appearance, compliance, and durability.

What We Can Customize

At PENGDE, we specialize in custom polyurethane solutions designed to meet the exact performance requirements of your applications. We offer customization across materials, shapes, dimensions, hardness, colors, and performance properties, covering a large variety of PU product categories, including but not limited to:

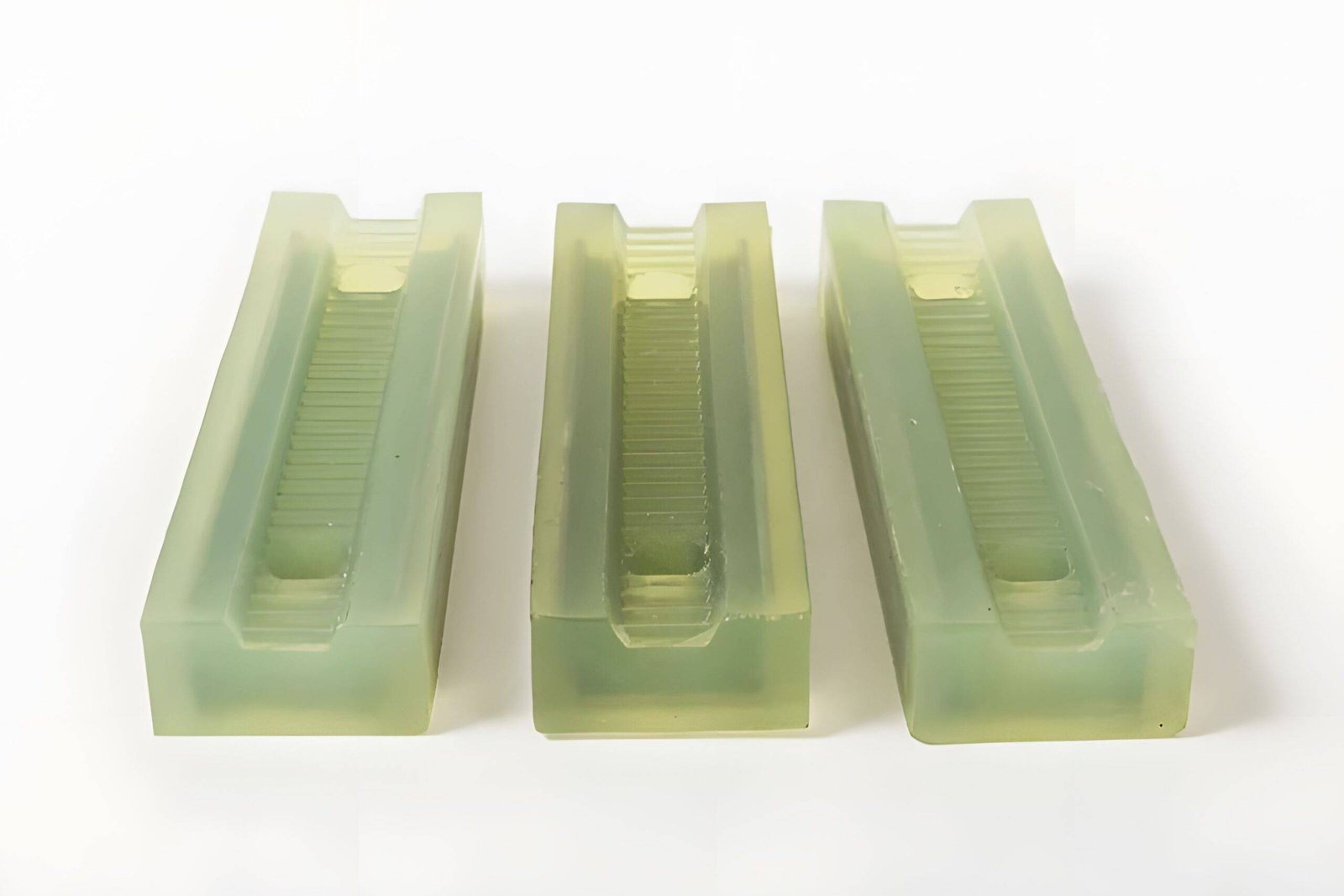

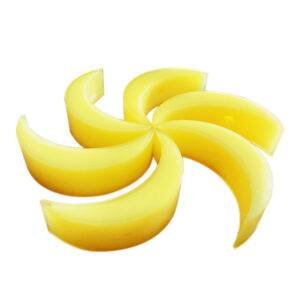

Custom molded urethane parts

Complex geometries for industrial and high-wear applications

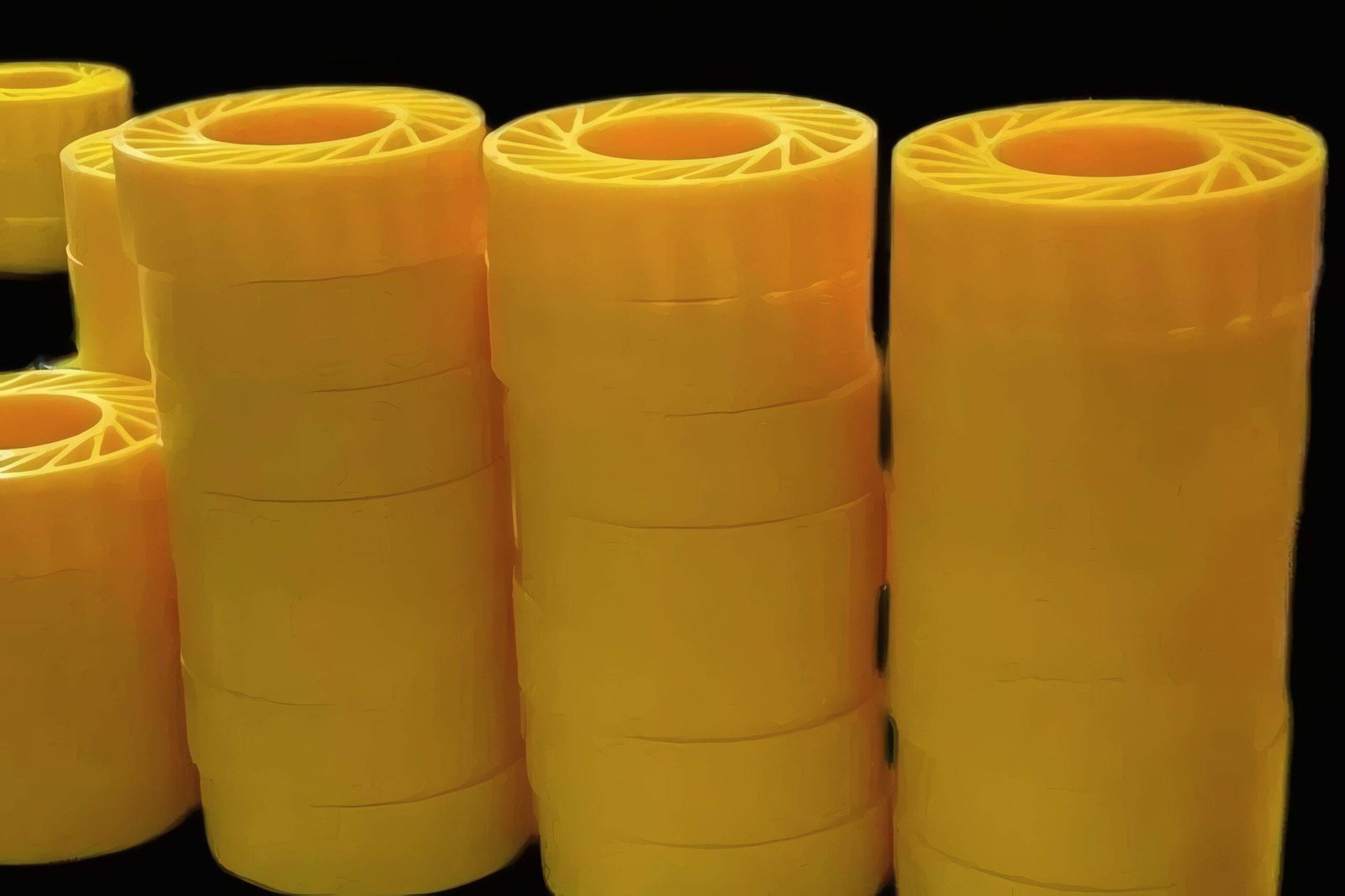

Custom urethane rollers and wheels

Used in conveyors, material handling equipment, ceramic machinery, and automated lines

Custom urethane bushings & gaskets

High-precision cushioning and sealing components with superior fatigue resistance

Cast polyurethane components

Ideal for small-batch or oversized parts where traditional molding is limited

Food-grade polyurethane parts

Safe and compliant for production lines in food and beverage industries

Polyurethane foam and cushioning parts

Lightweight shock-absorbing elements for packaging and machinery

Washer rings, anti-wear pads, PU liners, radius tooling for tile production, and other unique shapes

If you do not find your product on the list, no problem — we create fully custom PU parts from drawings, samples, or even a functional concept. Our engineering team helps you choose the right formulation and structure to achieve the best durability and economic performance.

Customization Capabilities

Our customization goes beyond the specifications you see — your idea becomes our next PU solution.

Material & Performance Customization | Details |

Hardness Range | Shore A10–A98 or Shore D for both soft and high strength PU parts |

Enhanced Durability | Wear resistant, tear resistant, impact resistant formulations |

Environmental Resistance | High or low temperature / Oil / Acid & alkali / Moisture resistant |

Outdoor Stability | UV resistant and anti aging properties |

Safety Grades | Food grade, medical grade, flame retardant, eco-friendly PU |

Lifetime Optimization | Tailored performance for extreme working conditions |

Structure & Appearance Customization | Details |

Geometry Freedom | Customized shapes and complex structures |

Insert & Overmolding | Metal cores and multi-material bonding |

Surface Options | Custom colors, textures and adjustable friction |

Dimensional Precision | Tolerance strictly follows drawings or samples |

One-Piece Molding | Fewer joints, reduced failure points |

Industries We Serve

Ceramics & Stone Processing

Rollers, sliders, gaskets, anti-wear pads, and more for tile and stone cutting, polishing, and transport equipment.

Industrial Machinery & Equipment

Bushings, wheels, rollers, vibration dampers, tooling covers, and more for heavy machinery and automation systems.

Food & Beverage

Food-grade rollers, conveyor wheels, seals, gaskets, and more for hygienic processing and packaging equipment.

Logistics & Material Handling

Wheels, rollers, bumpers, guides, and more for carts, conveyors, and handling systems.

Automotive & Transport

Bushings, rollers, seals, vibration pads, protective components, and more for machinery and vehicle assembly lines.

Printing & Packaging

Rollers, wheels, gaskets, tooling parts, and more for presses, laminators, and packaging machines.

The Process of Custom Polyurethane

Why Choose PENGDE

15+ Years PU Expertise

Trusted family-owned manufacturer with proven know-how.

Full Customization

Tailored materials, shapes, hardness, and coatings.

Why Choose PENGDE

Advanced Equipment

High-precision molding, casting, and tooling.

Strict Quality Control

Hardness, wear, chemical resistance, and dimensional accuracy guaranteed.

Global Experience

Serving industrial, ceramic, logistics, automotive, and food sectors.

One-Stop Partner

From prototyping to mass production and after-sales support.

FAQ About Custom Polyurethane Molding

A: We can customize a wide range of PU components, including rollers, wheels, bushings, gaskets, seals, radius tooling, and other industrial parts — from simple shapes to complex geometries.

A: MOQ depends on the part size, material, and complexity. We support both small-batch prototypes and large-scale production. Lead time varies accordingly, with rapid tooling and small-batch samples typically taking 2–4 weeks, and mass production schedules confirmed after sample approval.

A: Yes, our engineering team can help optimize designs for manufacturability, material selection, and performance. We produce high-precision prototypes using rapid tooling, small-batch casting, or RIM, ensuring accurate testing and validation before mass production.

Ready to Customize Your Polyurethane Parts?

Submit your drawings, samples, or specifications, and our engineering team will provide a tailored solution, from prototyping to mass production.