As industries strive for sustainability, the choice of conveyor belt materials plays a significant role in reducing environmental impact. Traditional materials like PVC and rubber have long been used, but they come with drawbacks such as high energy consumption, pollution, and limited recyclability. TPU (Thermoplastic Polyurethane) belts, on the other hand, offer a more eco-friendly solution. With their longer lifespan, energy efficiency, and recyclability, TPU belts are emerging as the greener option for industrial applications.

Reduced Waste and Longer Lifespan

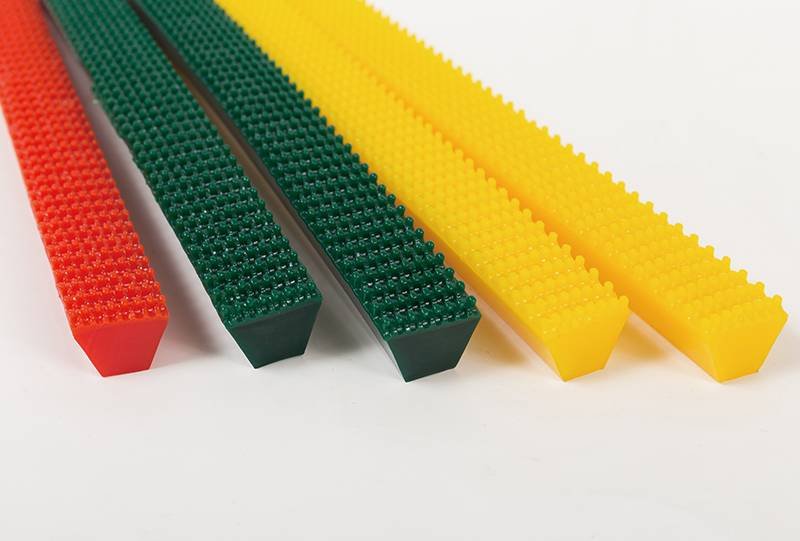

One of the biggest environmental advantages of TPU belts is their durability. Compared to PVC and rubber, TPU belts have a higher resistance to wear, abrasion, and tearing, which means they need to be replaced less frequently. Fewer replacements result in less industrial waste, lowering the overall environmental footprint.

Energy Efficiency in Conveyor Systems

TPU belts are lighter and more flexible than traditional rubber belts, reducing the strain on conveyor motors. This leads to lower energy consumption and improved efficiency in automated systems. For industries aiming to reduce carbon emissions, switching to TPU belts can contribute to significant energy savings over time.

Non-Toxic and Safe for Various Industries

Unlike PVC, which contains harmful plasticizers and chlorine, TPU is free from toxic chemicals. When exposed to heat or degradation, TPU does not release harmful dioxins, making it a safer choice for food processing, pharmaceuticals, and packaging industries. This non-toxic nature aligns with global environmental regulations, ensuring safer operations and compliance with sustainability goals.

Recyclability and Sustainable Manufacturing

TPU belts can be recycled and repurposed, unlike traditional rubber belts that often end up in landfills. Many TPU materials can be melted down and reused, reducing the demand for virgin raw materials. Additionally, modern TPU belt production methods require less water and fewer chemical treatments, making them a more sustainable choice from manufacturing to end-of-life disposal.

Resistance to Harsh Environments Reduces Chemical Waste

TPU belts offer excellent resistance to oils, chemicals, and extreme temperatures, making them ideal for industries where frequent cleaning and exposure to harsh substances are required. Their smooth, non-porous surface makes cleaning easier, reducing the need for harsh detergents and excessive water use. In contrast, rubber and PVC belts may require stronger chemicals for maintenance, contributing to pollution.

Conclusion

Switching to TPU belts is a smart choice for companies looking to enhance both operational efficiency and environmental responsibility. With less waste, lower energy consumption, and improved recyclability, TPU belts are helping industries move toward a greener and more sustainable future.

At PENGDE NEW MATERIAL TECHNOLOGY CO., LTD, we specialize in high-quality TPU belts designed for various industrial applications. To learn more about our eco-friendly TPU belt solutions, contact us at pengde2@pengde-pu.com.