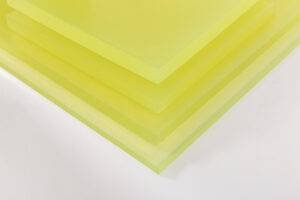

Polyurethane (PU) sheets are versatile materials widely used for insulation, industrial components, and construction applications. Thanks to their unique chemical composition, they offer an excellent strength-to-weight ratio, durability, and adaptability, making them increasingly popular across industries.

What Is a Polyurethane Sheet?

Polyurethane, also called polycarbamate, is a polymer composed of long-chain molecules with repeating units called monomers. Its molecular structure contains carbamate groups (-NHCO2), which give it remarkable flexibility, strength, and resilience.

PU sheets are produced as flat or shaped panels that can be customized for thickness, hardness, density, and even reinforced with other materials like fiberglass, steel, or graphite. This versatility allows PU sheets to be used in applications ranging from industrial rollers and gaskets to cushioning and protective panels.

Materials Used in PU Sheet Production

The main raw materials for PU sheets are:

- Polyols – Provide flexibility and elasticity, sourced from petroleum or natural oils.

- Diisocyanates (TDI) – React with polyols to form the polyurethane polymer.

- Additives – Pigments, stabilizers, or fillers to enhance color, mechanical properties, or other performance traits.

Step-by-Step PU Sheet Manufacturing Process

- Mixing

Polyols, diisocyanates, pigments, and other additives are blended in a computer-controlled mixing system. Agitators keep all components in a liquid state, ensuring uniformity. - Polymerization

The mixture is pumped through heated pipelines, where temperature is precisely controlled. A chemical reaction occurs, forming liquid polyurethane. - Foaming and Sheet Formation

The liquid polyurethane is dispensed onto a rolling conveyor belt, where it begins to expand like foam. Baking paper layers shape the foam into uniform sheets, forming a continuous block. - Curing

As the foam moves along the production line, it solidifies. The block is dried and cured, ensuring the sheets achieve the desired mechanical properties. - Cutting and Customization

Cured blocks are cut using automatic saws into sheets or sections as required. Standard block sizes can reach 120 meters in length, and sheets can be as thin as 1 mm. During cutting, sheets can also be reinforced or laminated with materials like fiberglass, steel, or graphite for added strength.

Other PU Sheet Manufacturing Methods

Besides the standard foaming process, PU sheets can also be produced using:

- Compression Molding – For high-density or structural sheets.

- Open Casting – Ideal for custom shapes or small batches.

- Centrifugal Casting – Produces uniform thickness sheets with precise dimensions.

Customization and Applications

Polyurethane sheets can be tailored for:

- Density, Hardness, and Resilience – From soft, sponge-like materials to rigid, load-bearing sheets.

- Thickness and Size – Depending on the project, sheets can be cut to custom dimensions.

- Composite Options – Integration with metals or fibers for enhanced strength.

Applications include: industrial wear parts, rollers, gaskets, insulation panels, vibration-damping pads, and protective surfaces.

Why Choose PU Sheets?

- Strength-to-Weight Ratio – Lightweight yet highly durable.

- Flexibility and Elasticity – Can withstand repeated stress and impact.

- Chemical and Heat Resistance – Suitable for harsh industrial environments.

- Customizable – Easily tailored to meet specific project requirements.

About PENGDE PU Products

Founded in 2008 in Foshan, China, PENGDE specializes in high-quality polyurethane products. With extensive experience in producing PU sheets, we offer:

- Custom hardness, thickness, and density options

- Reinforced composite sheets for load-bearing applications

- OEM and ODM services for industrial and construction needs

Contact us: pengde2@pengde-pu.com