In many cases, finding the right materials for your manufacturing goals can seem challenging, but this really shouldn’t have to be the case if you ask us. In line with this, today, we’re looking at some of the key differences you should know about TPUs (thermoplastic polyurethanes) and PVCs (Polyvinyl Chloride) to help inform your decision on the optimal material overall.

What is TPU?

First up, let’s take a look at what TPU is and how it might work for your project. TPU stands for thermoplastic polyurethane, a specialist type of block polymer increasingly used in modern manufacturing processes.

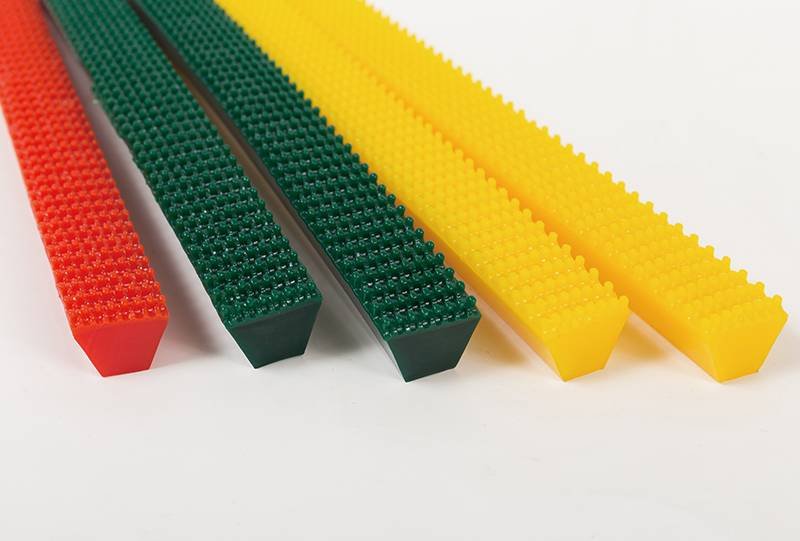

Though it technically falls into neither category neatly, TPU (among other forms of polyurethanes), offers many of the same benefits as both rubber and plastic, making it a hugely versatile material for many applications. What’s more, as a thermoplastic material, it can be melted and molded easily, thereby allowing the material to be used in a wide array of applications.

What is PVC?

PVC is one of the most well-known materials on the market these days, becoming something of a household name in many cases! PVC, otherwise known as Polyvinyl Chloride, is a widely used synthetic polymer that’s produced from made from vinyl chloride monomers, giving numerous properties that are often highly valuable in many cases.

Which is Better: TPU vs PVC?

Determining whether TPU or PVC is better is something of a challenge, owing to the very different properties of the two materials. However, overall, TPU may offer greater flexibility in terms of the range of applications and its elasticity directly.

Notably, this allows TPU to be used in a huge array of applications where repeated deformation and reformation are needed, such as in footwear and clothing, as well as many devices and moving parts. It’s most valued for its excellent softness and elasticity. In fact, TPU can potentially be stretched to twice its normal length!

However, if you’re looking for a cost-effective, affordable solution, few products can beat the value-for-money offered by PVC. Thus, if cost is an important factor in your decision, this may be well worth keeping in mind. It’s also much more rigid than TPU materials, making PVC popular for applications such as pipes and the like where stretching and elasticity are not particularly important as part of the final decision.

Fortunately, many manufacturers would be happy to provide a quote if you’re struggling to make this choice, which may help you decide which material fits comfortably within your brand’s budget.

Final Thoughts

There are many benefits associated with both PVC and TPU materials, and deciding between the two can naturally feel like a struggle for many people. However, if you ask us, this shouldn’t have to be difficult, and so our experts are always on hand if you need further support with this decision. Remember: there’s a specialist type of material out there for almost every application, and our experts can help you decide whether or not TPU might fit the criteria for your project. Please don’t hesitate to contact us at pengde2@pengde-pu.com.