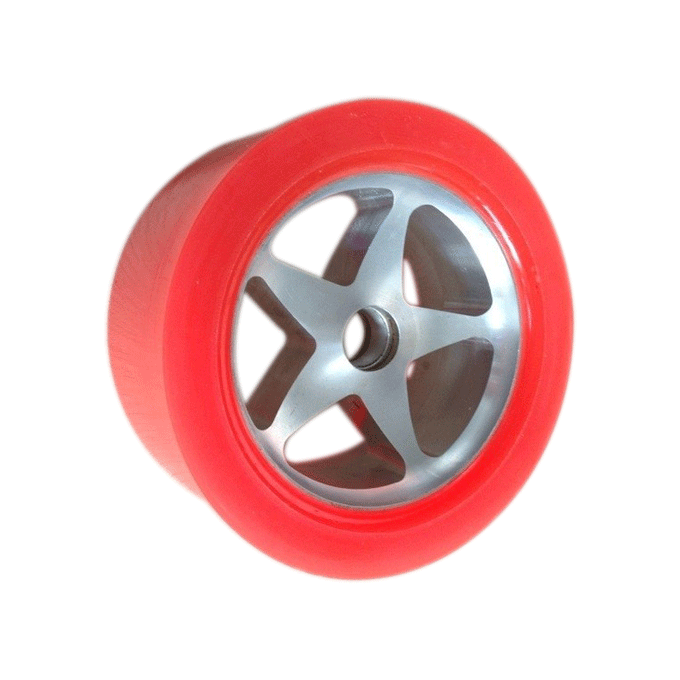

Polyurethane Conveyor Roller

Polyurethane Conveyor Roller

Our polyurethane conveyor rollers are designed for reliable material handling in industrial conveyor systems. Manufactured with high-quality PU materials, these rollers provide excellent wear resistance, shock absorption, and quiet operation compared to traditional rubber or metal rollers.

Specifications

- Material: Polyurethane (PU)

- Roller Type: Conveyor roller / drive roller / support roller

- Outer Diameter: Customizable

- Roller Length: Customizable

- Shaft Type: Fixed shaft or spring-loaded shaft

- Hardness: Multiple Shore A options

- Surface Finish: Smooth or textured

- Color: Standard or custom

- Load Capacity: Designed for industrial material handling

- Chemical Resistance: Resistant to oil, grease, and industrial contaminants

Key Features

- Excellent Wear & Abrasion Resistance

Ideal for continuous conveyor operation - Low Noise & Smooth Running

Reduces operational noise compared to metal rollers - High Elasticity & Shock Absorption

Protects conveyed products from impact damage - Strong Load-Bearing Capacity

Suitable for light to heavy-duty conveyor systems - Chemical & Oil Resistance

Performs reliably in industrial environments - Customizable Design

Roller size, hardness, shaft, and surface can be tailored

Applications

- Conveyor and material handling systems

- Logistics and warehousing equipment

- Packaging and sorting lines

- Ceramic and building material production

- Food and beverage processing conveyors

- OEM conveyor equipment manufacturing

Customization & Supply Capability

- Rollers produced based on drawings or samples

- Custom diameter, length, hardness, and shaft design

- Small-batch prototyping and volume production

- OEM and replacement conveyor rollers

FAQ

Q1: What are polyurethane conveyor rollers used for?

They are used in conveyor systems to transport materials smoothly while reducing noise, wear, and product damage.

Q2: Why choose PU conveyor rollers instead of rubber or steel rollers?

PU rollers offer better wear resistance, quieter operation, and longer service life while being gentle on conveyed items.

Q3: Can polyurethane conveyor rollers be customized?

Yes, roller size, hardness, shaft type, and surface finish can be customized to your conveyor system.

Q4: Are PU conveyor rollers suitable for continuous operation?

Yes, they are designed for long-term, continuous industrial use.

Q5: Which industries commonly use PU conveyor rollers?

Logistics, packaging, ceramics, food processing, manufacturing, and OEM conveyor equipment industries.