Polyurethane Jaw Coupling

Polyurethane Jaw Coupling

Our jaw couplings feature high-quality polyurethane elastomer inserts, engineered for reliable torque transmission while reducing vibration and compensating for slight misalignment in industrial machinery. With a combination of metal hubs and resilient PU jaws, these couplings deliver smooth, durable, and maintenance-friendly operation.

Specifications

- Material: Polyurethane (PU) elastomer insert with steel or aluminum hubs

- Coupling Type: Jaw coupling / Elastomeric coupling

- Torque Capacity: Depending on size and PU hardness

- Bore Size: Standard and customizable

- Hub Material: Steel, aluminum, or stainless steel

- Elastomer Hardness: Shore A options for flexible torque damping

- Misalignment Compensation: Angular and parallel

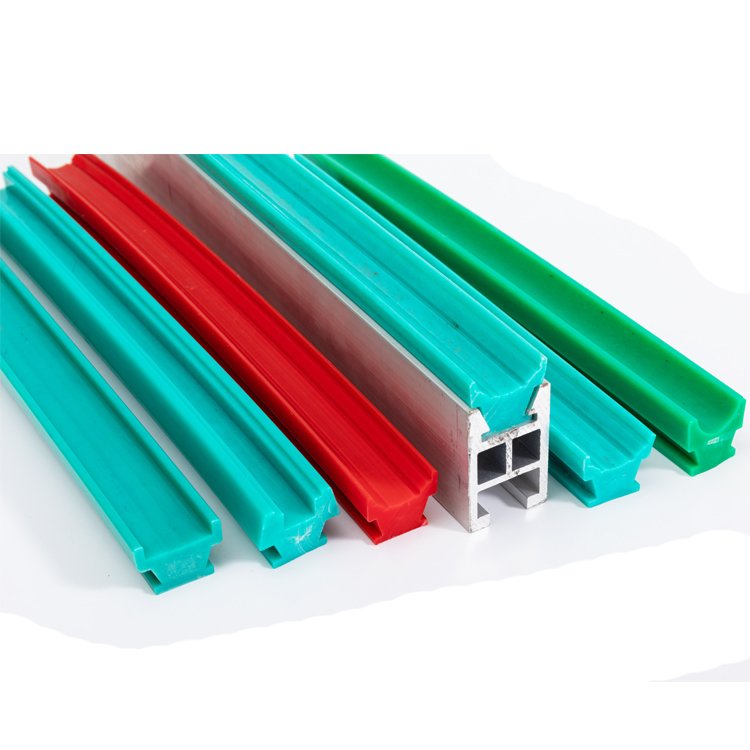

- Color: Standard (black/orange) or custom

Key Features & Performance Advantages

- Excellent Vibration & Shock Damping

Reduces stress on shafts and connected equipment - High Wear & Fatigue Resistance

Long service life under continuous operation - Flexible Misalignment Compensation

Protects machinery from angular, parallel, and axial misalignment - Customizable Hardness & Size

Tailored to torque requirements and shaft dimensions - Smooth & Quiet Operation

Reduces operational noise and improves mechanical efficiency - Easy Installation & Replacement

Designed for fast maintenance with standard hubs

Applications

- Conveyors and material handling systems

- Pumps and compressors

- Industrial automation equipment

- CNC and machining centers

- Packaging and printing machinery

- Motors and general mechanical power transmission

Customization & Supply Options

- PU elastomer inserts in different hardness levels

- Standard or custom bore sizes

- OEM and replacement jaw couplings

- Small and bulk batch supply available

FAQ

Q1: What is a jaw coupling used for?

Jaw couplings transmit torque between two shafts while damping vibration and compensating for minor misalignments.

Q2: Why use PU elastomer inserts instead of rubber?

PU provides higher wear resistance, better chemical and oil resistance, and longer service life compared to traditional rubber inserts.

Q3: Can jaw couplings be customized for my machine?

Yes, bore size, hub material, elastomer hardness, and overall dimensions can be customized.

Q4: How does a jaw coupling reduce vibration?

The PU elastomer insert absorbs torsional shocks and dampens vibrations between connected shafts.

Q5: Which industries use jaw couplings?

Jaw couplings are widely used in industrial automation, material handling, CNC machinery, pumps, compressors, and packaging systems.