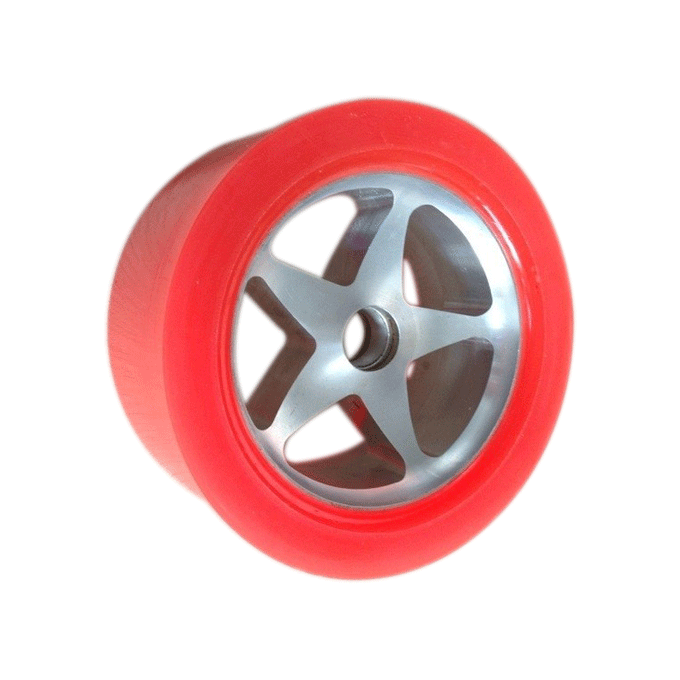

Polyurethane Wheel

Polyurethane Wheel

Polyurethane wheels are engineered to deliver exceptional durability, load-bearing performance, and smooth rolling in demanding industrial environments. Made from high-quality polyurethane elastomer, these wheels combine the toughness of plastic with the elasticity of rubber, providing excellent abrasion resistance, shock absorption, and long service life.

Product Specifications

- Material: Premium polyurethane elastomer (PU)

- Wheel Diameter: Customizable based on application

- Width & Thickness: Standard or custom options available

- Hardness Range: Multiple Shore A grades for different load conditions

- Core Options: Steel core, aluminum core, or solid PU

- Bearing Type: Ball bearing, roller bearing, or plain bore

- Color Options: Standard or custom colors

- Load Capacity: Designed for light-duty to heavy-duty applications

Key Features & Performance Advantages

- Outstanding Wear Resistance

Significantly longer lifespan than rubber or plastic wheels - High Load Capacity

Supports heavy equipment without deformation - Excellent Shock Absorption

Reduces vibration and protects machinery - Low Noise Operation

Smooth rolling with minimal sound - Oil, Grease & Chemical Resistant

Suitable for harsh industrial environments - Custom Engineered Solutions

Sizes, cores, and hardness tailored to specific equipment

Typical Applications

- Conveyor systems and production lines

- Forklifts and pallet handling equipment

- Automated machinery and robotics

- Warehousing and logistics carts

- Ceramic and packaging machinery

- Heavy-duty industrial transport systems

Customization & OEM Services

- Custom diameters, widths, and profiles

- Different hardness grades for load and speed optimization

- Integrated metal hubs or reinforced cores

- Precision machining for shafts and bearings

- OEM production based on drawings or samples

FAQ

Q1: Why choose polyurethane wheels over rubber or nylon wheels?

PU wheels offer better wear resistance, higher load capacity, and longer service life while maintaining smooth and quiet operation.

Q2: Are polyurethane wheels suitable for heavy-duty applications?

Yes, they are commonly used in forklifts, conveyors, and industrial equipment requiring high strength and durability.

Q3: Can PU wheels be customized?

Yes, dimensions, hardness, core materials, and bearing systems can all be customized.

Q4: Do polyurethane wheels resist oil and chemicals?

PU material performs well in environments exposed to oil, grease, and many chemicals.

Q5: How do I select the right wheel hardness?

Softer wheels provide better shock absorption, while harder wheels offer higher load capacity and wear resistance. Our team can assist with selection.