PU Hose with Reinforced Steel

PU Hose with Reinforced Steel

PU Hose with Reinforced Steel is a flexible hose specially designed for high-wear and complex working conditions. It adopts an embedded spiral steel wire reinforcement structure and a permanently anti-static polyurethane tube wall. Suitable for the safe transportation of dust, particles, gases and liquids, it is widely used in industrial dust removal, chemical transmission, municipal environmental sanitation and other fields.

Application Scenarios

Industrial Manufacturing and Equipment Supporting

- Electronic manufacturing: Dust removal for printed circuit board (PCB) drilling machines; clean-room ventilation for semiconductor production equipment

- Printing and packaging: Air supply systems for offset printing machines; air transmission for UV/IR dryers; ink-mist recovery

- Surface treatment: Dust extraction for shot-blasting and sandblasting equipment (shot-blasting rooms, shipyards, grinders)

- Textile industry: Fiber dust extraction for spinning machines, knitting machines, and looms

Hazardous Environments

- Explosion hazard areas: Pneumatic conveying of flammable dust in Zones 20/21/22

Municipal and Environmental Protection Equipment

- Sanitation vehicles: Dust removal systems for sweepers, floor sweepers, lawn mowers, and leaf blowers/collectors

- Industrial cleaning: Dust collectors, floor-cleaning machines, and oil mist recovery devices

Other Special Scenarios

- Agricultural ventilation: Barn ventilation and air circulation in livestock pens

- Compressor systems: Connection pipelines for side-channel blowers, vacuum pumps, and pressure pumps

- Heating protection: External protective hoses

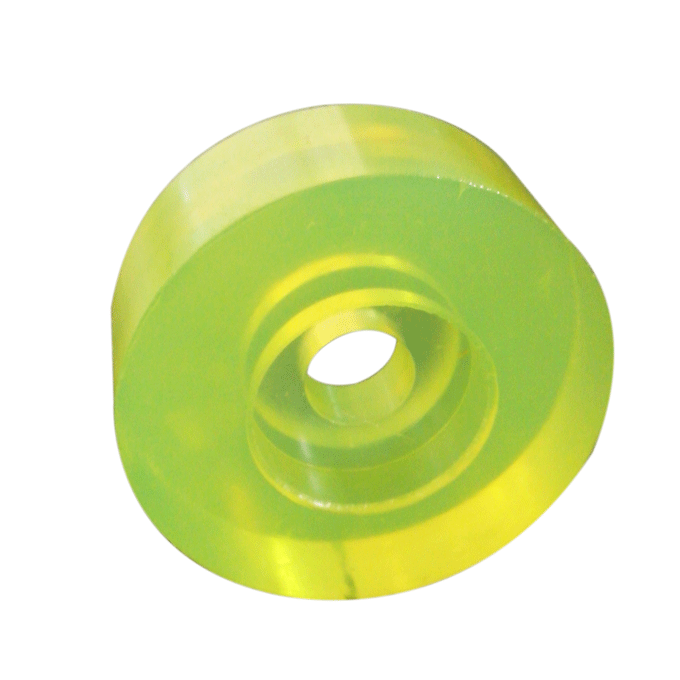

Product Structure and Characteristics

Structural Design

- Reinforcement layer: Elastic steel wire is spirally embedded in the wall of the PU steel wire reinforced hose, forming a high-strength supporting structure that is pressure-resistant and anti-collapse.

- Hose wall material: Permanently anti-static polyester polyurethane with a thickness of about 0.7 mm.

Performance Advantages

- High wear resistance: Medium-heavy duty design, suitable for long-term transportation of abrasive powders and particles through the PU Steel Wire Reinforced Hose.

- Chemical resistance: Resistant to oil, gasoline, weak acids, alkalis and various chemical erosion.

- Anti-static property: Surface resistance <10⁹ Ω (complying with NFPA 652 standard), eliminating static accumulation in the PU Steel Wire Reinforced Hose.

- Flame retardant grade: UL94-V2 (American standard), DIN 4102-B1 (German standard)

- Temperature adaptability:

- Standard version: -40°C to +100°C (short-term +125°C)

- Custom version: -40°C to +125°C (short-term +150°C)

Product Specifications

| Inner Diameter

(mm) |

Outer Diameter

(mm) |

Positive Pressure

(bar) |

Negative Pressure

(bar) |

Bending Radius

(mm) |

Weight

(kg/m) |

Length

(m) |

| 25 | 32 | 2.445 | 0.755 | 23 | 0.19 | 20 |

| 30 | 37 | 2.055 | 0.63 | 26 | 0.25 | 20 |

| 32 | 39 | 1.93 | 0.59 | 27 | 0.27 | 20 |

| 38 | 45 | 1.635 | 0.495 | 31 | 0.31 | 20 |

| 40 | 47 | 1.555 | 0.47 | 32 | 0.33 | 20 |

| 45 | 52 | 1.39 | 0.42 | 35 | 0.37 | 20 |

| 50 | 57 | 1.25 | 0.38 | 38 | 0.4 | 20 |

| 55 | 62 | 1.14 | 0.345 | 41 | 0.44 | 20 |

| 60 | 67 | 1.05 | 0.315 | 44 | 0.48 | 20 |

| 65 | 70 | 0.97 | 0.29 | 47 | 0.52 | 20 |

| 70 | 77 | 0.9 | 0.185 | 50 | 0.56 | 20 |

| 75 | 82 | 0.84 | 0.175 | 53 | 0.59 | 20 |

| 80 | 87 | 0.79 | 0.16 | 56 | 0.64 | 20 |

| 90 | 97 | 0.705 | 0.145 | 62 | 0.72 | 20 |

| 100 | 107 | 0.635 | 0.135 | 68 | 0.8 | 20 |

| 110 | 117 | 0.575 | 0.125 | 74 | 0.87 | 20 |

| 115 | 122 | 0.55 | 0.12 | 77 | 0.9 | 20 |

| 120 | 127 | 0.53 | 0.115 | 80 | 0.95 | 20 |

| 125 | 132 | 0.51 | 0.11 | 83 | 0.98 | 20 |

| 130 | 137 | 0.49 | 0.105 | 86 | 1.01 | 20 |

| 140 | 147 | 0.455 | 0.095 | 92 | 1.09 | 20 |

| 150 | 157 | 0.425 | 0.075 | 98 | 1.4 | 20 |

| 160 | 167 | 0.4 | 0.07 | 104 | 1.5 | 10 |

| 170 | 177 | 0.375 | 0.065 | 108 | 1.58 | 10 |

| 175 | 182 | 0.365 | 0.065 | 113 | 1.63 | 10 |

| 180 | 187 | 0.355 | 0.06 | 116 | 1.67 | 10 |

| 200 | 207 | 0.32 | 0.055 | 128 | 1.86 | 10 |

| 225 | 232 | 0.285 | 0.05 | 143 | 2.08 | 10 |

| 250 | 257 | 0.255 | 0.045 | 158 | 2.31 | 10 |

| 254 | 261 | 0.25 | 0.045 | 160 | 2.35 | 10 |

| 275 | 282 | 0.23 | 0.04 | 173 | 2.54 | 10 |

| 280 | 287 | 0.23 | 0.04 | 176 | 2.59 | 10 |

| 300 | 307 | 0.215 | 0.035 | 188 | 2.77 | 10 |