In industrial manufacturing, choosing the right materials for operational processes is essential for ensuring efficiency, durability, and cost-effectiveness. One material that has proven its worth across various industries is TPU (Thermoplastic Polyurethane). TPU belts are increasingly becoming the preferred choice for many industrial applications due to their superior properties, including durability, flexibility, and chemical resistance. In this article, we’ll explore the advantages of TPU belts and why they are transforming industrial operations worldwide.

What Are TPU Belts?

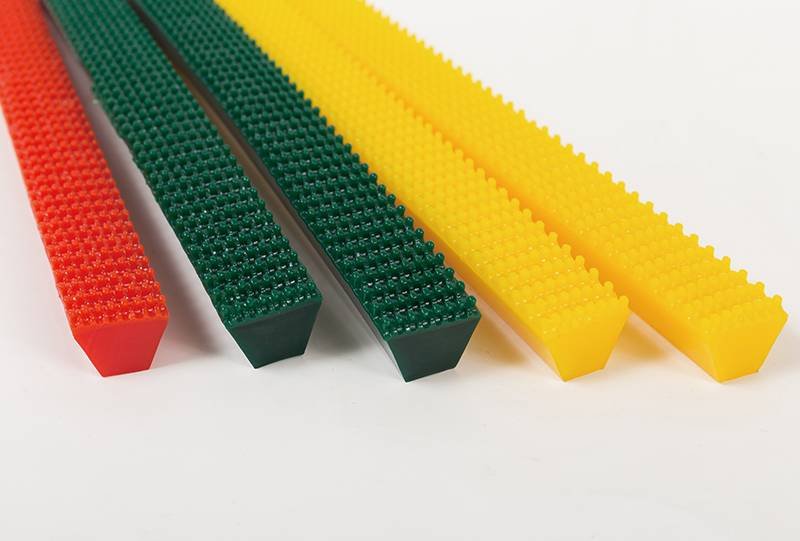

TPU belts are belts made from thermoplastic polyurethane, a versatile material known for its high-performance characteristics. TPU is a type of plastic that combines the flexibility of rubber with the toughness of plastic, making it perfect for use in various industrial conveyor systems and machinery. These belts are highly sought after in industries such as automotive, food processing, packaging, textile manufacturing, and more, owing to their remarkable abrasion resistance, high tensile strength, and ability to withstand extreme conditions.

Advantages of TPU Belts in Industrial Applications

1. Superior Durability

One of the primary reasons TPU belts are gaining popularity in industrial settings is their exceptional durability. Thermoplastic polyurethane is well-known for its abrasion resistance and wear resistance, making TPU belts ideal for high-stress environments where other materials such as rubber or PVC might wear out quickly. This increased durability results in longer lifespan, which reduces the frequency of replacements, ultimately saving businesses both time and money on maintenance costs.

2. High Flexibility and Strength

In industrial applications, flexibility and strength are critical. TPU belts excel in both of these areas. They maintain high tensile strength while being highly flexible, even under heavy loads. This makes them suitable for various tasks, from heavy-duty conveyor systems to high-speed machinery. Whether in the automotive industry or textile manufacturing, TPU belts can handle a wide range of applications with ease, offering reliable performance and increased productivity.

3. Resistance to Chemicals and Oils

Many industrial environments expose materials to harsh chemicals, oils, and other corrosive substances. TPU belts stand out in these conditions due to their chemical resistance. Unlike traditional rubber or PVC belts, which degrade when exposed to oils or solvents, TPU belts maintain their structural integrity and continue to perform effectively. This chemical resistance is particularly advantageous in industries like food processing, pharmaceuticals, and chemical manufacturing, where cleanliness and operational efficiency are paramount.

4. Temperature Resistance

Whether it’s extreme heat or cold temperatures, TPU belts are engineered to withstand a wide range of temperatures, making them versatile in various industrial applications. Unlike other materials that may crack, soften, or lose their effectiveness at high or low temperatures, TPU belts maintain their flexibility and strength. This makes them ideal for environments with fluctuating temperatures, such as cold storage facilities or industries that involve high-heat processing.

5. Eco-Friendly and Sustainable

In today’s world, sustainability is becoming more important than ever, and businesses are seeking eco-friendly solutions. TPU belts offer an environmentally friendly alternative to traditional materials. Thermoplastic polyurethane is recyclable, making it a sustainable material choice for industries looking to minimize their environmental footprint. Additionally, TPU’s longevity reduces the need for frequent replacements, further contributing to sustainability efforts.

6. Versatility in Industrial Applications

TPU belts are incredibly versatile, making them suitable for a wide range of industrial applications. From automotive assembly lines to food packaging systems, textile processing, and conveyor systems, TPU belts are designed to meet the specific needs of different industries. Their ability to handle heavy loads, operate in extreme conditions, and provide high-speed functionality makes them indispensable in numerous sectors.

7. Low Maintenance and Cost-Effective

Since TPU belts are highly durable and require less frequent maintenance, they provide long-term cost savings. Their superior wear resistance means they don’t need to be replaced as often as belts made from other materials. Moreover, the reliable performance of TPU belts reduces downtime in production lines, contributing to higher productivity and greater overall efficiency.

Common Applications of TPU Belts

1. Automotive Industry

In the automotive industry, TPU belts are used in assembly lines for the smooth and efficient transportation of parts. Their durability and resistance to wear ensure that automotive production processes run smoothly with minimal interruptions.

2. Food Processing and Packaging

Food-grade TPU belts are widely used in food processing and packaging due to their non-toxic properties, chemical resistance, and ability to meet FDA regulations. These belts are ideal for conveying food items through production lines without contaminating or compromising quality.

3. Textile Manufacturing

In textile manufacturing, TPU belts are used in various processes like spinning, weaving, and material handling. Their flexibility and strength ensure smooth operations in high-speed environments, while their abrasion resistance prevents damage to delicate fabrics.

4. Conveyor Systems

Conveyor systems in warehouses, factories, and distribution centers benefit from TPU belts due to their high load-bearing capacity and ability to withstand heavy-duty usage. TPU belts ensure continuous and efficient material handling, making them a critical component of logistics operations.

Conclusion

The numerous advantages of TPU belts make them a smart choice for industries looking to improve efficiency, reduce downtime, and cut maintenance costs. Their superior durability, chemical resistance, temperature tolerance, and flexibility make them ideal for a variety of industrial applications. Whether in automotive assembly lines, food processing, or textile manufacturing, TPU belts provide a reliable, cost-effective solution.

At PENGDE NEW MATERIAL TECHNOLOGY CO., LTD, we specialize in providing high-quality TPU belts that cater to a wide range of industrial needs. Our products are designed to meet the highest standards of performance, ensuring long-term value and durability. For more information about our TPU belts or to inquire about custom solutions, feel free to contact us at pengde2@pengde-pu.com.