The food industry is on a constant evolution. Automation is popping out here and there with state-of-the-art machinery with a TPU belt to introduce more hygiene, efficiency, and safety into the entire handling and process. Hence, considering the growing population within this niche, any food processor that fails to improve on their daily production and operations will plunge into extinction before you know it.

The choice of conveyor belt, to a great extent, dictates how streamlined the entire process is. They are necessary for a number of applications including water separation, slicing, and descaling, to mention a few.

So, when it comes to picking a choice in this regard, TPU belts and PVC are names that come to mind. But now, the question is: is the TPU belt truly the best for machines in the food industry?

Is the TPU belt the best for food processing machines?

Yes, TPU, Thermoplastic Polyurethane, makes the best conveyor belt for food processing machines. And you’ll agree with this by the end of this guide. The material offers a superior choice when it comes to applications that demand high performance. It embodies a number of vital properties that are typically absent in most similar polymers.

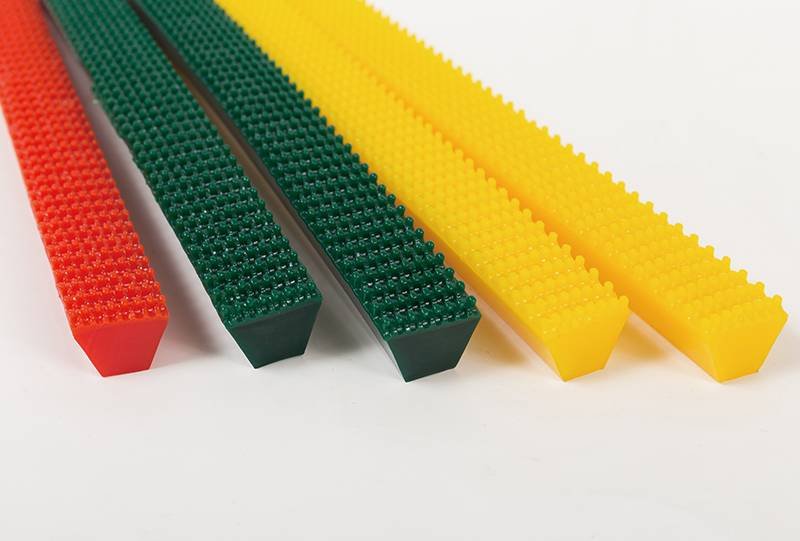

Thermoplastic Polyurethane belts are available in different forms. This is based on the features inherent to them, their particular nature, and several other criteria. Still, there are some unique and compelling features that are inherent to every one of these materials. For instance, compared to other materials of similar scale, they have a relatively higher wear and abrasion resistance. Not to mention how well they resist lipids, animals, vegetables, and other components that can be potentially inimical to their nature and quality.

Considering these reasons, the TPU belt has gained prevalence and traction in very high demanding processes and niches. An example is in confectionery processes. These processes typically require high adaptability to temperature fluctuations, terrific abrasive property, and a surface that allows for easy cleaning. These features, and several others, are what the TPU belt embodies quite well. And that’s not all.

It goes without saying that you’re spoilt for choice when it comes to TPU belts. Depending on your needs, you will find belts tailored perfectly. For instance, there are belts with superior hydrolysis resistance, offering elevated flexibility even at a very low temperature. Even if you want a material to offer you greater thermal oxidation, you’d find something that fits your bill just perfectly with TPU.

With TPU, you can as well get a material offering a sleek surface with bacterial deposit resistance. As such, the material is very easy to clean and maintain. While TPU is relatively more expensive than most options there, the long-term costs in terms of maintenance, longevity, and potential replacement are sure to compensate for the high upfront. So, if you’re viewing the price from a long-term viewpoint, it is ultimately cheaper.

At the upfront price as well, you are undoubtedly getting the value for the money spent. The material is suitable for a number of modern processes, extending beyond foods regardless of their requirements and belt contact demands.

For further questions, please contact us at pengde2@pengde-pu.com.