In industrial and commercial conveyor systems, choosing the right belt material is crucial for efficiency, durability, and cost-effectiveness. Traditionally, PVC belts and rubber belts have been the go-to options for various industries. However, TPU (Thermoplastic Polyurethane) belts are emerging as the superior choice, offering higher durability, flexibility, and hygiene standards.

With industries such as food processing, packaging, logistics, and manufacturing demanding longer-lasting, more efficient solutions, TPU belts are proving to be the future of conveyor technology. In this article, we will compare TPU vs. PVC vs. rubber belts and explore why TPU is the better long-term investment.

1. What Are TPU, PVC, and Rubber Belts?

Before diving into comparisons, let’s define the three types of conveyor belts:

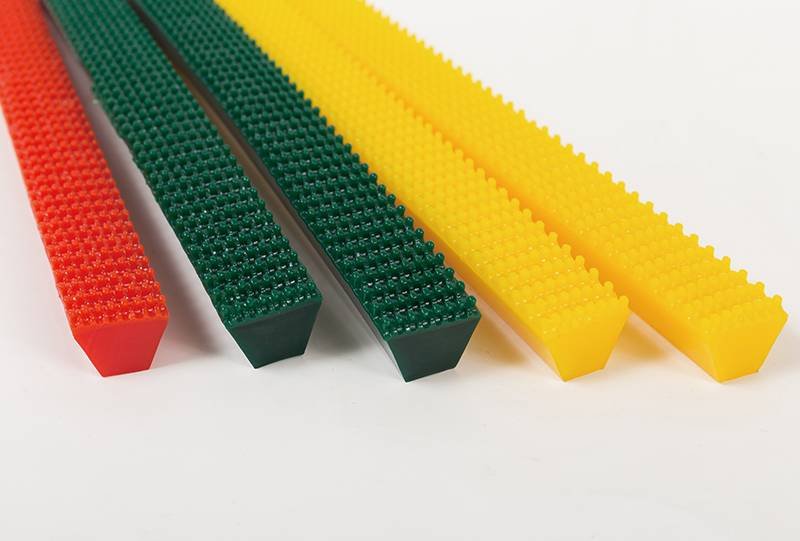

- TPU Belts (Thermoplastic Polyurethane) – Made from high-quality polyurethane, these belts offer excellent wear resistance, flexibility, and hygiene, making them ideal for industries requiring precision and cleanliness.

- PVC Belts (Polyvinyl Chloride) – Made from synthetic plastic material, PVC belts are commonly used for light to medium-duty applications but lack durability under harsh conditions.

- Rubber Belts – Traditionally used in heavy-duty applications, rubber conveyor belts provide high strength but are heavier, harder to clean, and less resistant to chemicals and oils.

2. TPU vs. PVC vs. Rubber: A Feature-by-Feature Comparison

Durability and Wear Resistance

- TPU Belts – Highly resistant to abrasion, wear, and tears, TPU belts have a longer lifespan compared to both PVC and rubber. They can withstand frequent bending and stretching without cracking or hardening.

- PVC Belts – PVC belts tend to degrade faster under high friction and heavy loads, leading to more frequent replacements.

- Rubber Belts – Rubber belts are durable but prone to aging, cracking, and hardening over time, especially when exposed to oils, chemicals, or extreme temperatures.

- Winner: TPU Belts – Their superior wear resistance means fewer replacements and lower long-term costs.

Hygiene and Cleanability

- TPU Belts – TPU belts are non-porous, resistant to bacteria, and easy to clean, making them perfect for food processing, pharmaceuticals, and hygiene-sensitive industries. TPU belts are also FDA and EU food-grade approved.

- PVC Belts – PVC belts have a porous surface, making them prone to contamination in food and medical applications. They are harder to sanitize and may absorb oils and moisture over time.

- Rubber Belts – Rubber belts are challenging to clean and can trap bacteria due to their textured and porous surface. They also absorb grease, oils, and chemicals, making them unsuitable for strict hygiene environments.

- Winner: TPU Belts – Their easy-to-clean surface and compliance with food safety regulations give them an advantage in hygienic industries.

Flexibility and Energy Efficiency

- TPU Belts – TPU belts are lighter and more flexible, reducing strain on conveyor motors and lowering energy consumption. They also work efficiently in curved or inclined conveyor systems.

- PVC Belts – PVC belts are stiff and can become brittle over time, making them less effective in high-flexibility applications.

- Rubber Belts – Heavy and less energy-efficient, rubber belts increase operational costs due to higher motor power requirements.

- Winner: TPU Belts – Their lightweight and flexible design results in lower energy consumption and smoother operation.

Chemical and Oil Resistance

- TPU Belts – TPU is highly resistant to oils, greases, and industrial chemicals, making it ideal for food production, automotive, and chemical industries.

- PVC Belts – PVC belts can absorb oils and chemicals, leading to degradation and reduced lifespan.

- Rubber Belts – Rubber belts deteriorate when exposed to oils, solvents, and harsh chemicals, requiring frequent replacements in certain industries.

- Winner: TPU Belts – Their superior chemical resistance ensures longer operational life in oil- and grease-prone environments.

Temperature Resistance

- TPU Belts – TPU belts can withstand extreme temperatures, from -40°C to 80°C (-40°F to 176°F), making them suitable for freezing, refrigeration, and high-heat applications.

- PVC Belts – PVC belts become brittle in cold environments and can warp under high heat.

- Rubber Belts – Rubber belts can handle high temperatures but may crack in low temperatures, limiting their use in freezing applications.

- Winner: TPU Belts – Their wide temperature range makes them versatile across industries.

Limitations of TPU Belts

While TPU conveyor belts offer many advantages, they are not without limitations in certain conditions:

- Not Ideal for Extremely Hot Wash Processes: TPU may soften under prolonged high-temperature wash cycles above typical industrial ranges.

- Higher Initial Cost: Initial purchase cost is usually higher than PVC or rubber, which may deter budget-only focused buyers.

- Specific Industry Constraints: In some specialized applications like heavy metal scrap handling or extremely abrasive materials, rubber belts with specific heat/cut-resistant treatments may still be preferred.

Cost Efficiency

- TPU Belts – While TPU belts have a higher initial cost, they offer a longer lifespan, reduced maintenance, and lower energy consumption, making them more cost-effective over time.

- PVC Belts – Cheaper initially but frequent replacements lead to higher long-term costs.

- Rubber Belts – Durable but high maintenance and energy-intensive, increasing operating expenses.

- Winner: TPU Belts – Long-term savings outweigh the initial investment.

TPU Belt Total Cost of Ownership (TCO)

Understanding cost is more than looking at upfront pricing — total cost of ownership includes maintenance, energy use, downtime, and replacement frequency. While PVC and rubber belts may be cheaper initially, TPU belts often outperform in long-term economic value:

- Maintenance Costs: TPU belts require less frequent repair due to superior wear resistance.

- Energy Use: Higher flexibility and lighter weight reduce motor strain and power consumption.

- Replacement Frequency: Longer lifespan means fewer installations and less downtime.

- Downtime Savings: Reduced stoppages from belt failure can significantly increase productivity.

Overall, many industrial users find that TPU conveyor belts deliver a lower total cost of ownership over the system’s lifetime, especially in high-load, high-wear environments.

3. How to Choose the Right Conveyor Belt Material

Selecting the right conveyor belt material depends on your specific application:

- Light-Duty vs Heavy-Duty: For lightweight food, packaging, and logistics applications, PVC may suffice. For heavy materials or harsh environments, TPU or rubber are better choices.

- Hygiene Requirements: If sanitation and cleanliness are critical (e.g., food or pharmaceuticals), prioritize TPU or food-grade PVC.

- Temperature Range: For very high-heat applications, some rubber formulations perform well, but TPU’s broader range often suits dynamic industrial settings.

- Chemical Exposure: If your process involves oils, solvents, or greases, TPU’s chemical resistance outperforms PVC and rubber.

- Energy and Flexibility Needs: For curved, inclined, or high-speed conveyors, TPU’s flexibility and lightweight design reduce energy consumption and improve dynamics.

4. Why TPU Belts Are the Future

With industries moving toward energy-efficient, durable, and sustainable solutions, TPU belts outperform PVC and rubber in almost every category. From food processing and pharmaceuticals to automotive and logistics, TPU belts provide long-term reliability, safety, and cost-effectiveness.

Key Reasons TPU Is the Future:

✔ Longer lifespan → Reduced replacements and lower maintenance costs

✔ Hygienic and easy to clean → Ideal for food and medical industries

✔ Energy-efficient and flexible → Reduces operational costs

✔ Resistant to chemicals, oils, and extreme temperatures

✔ Compliant with food-grade safety regulations (FDA, EU standards)

Industries That Benefit Most from TPU Belts:

🏭 Food Processing & Packaging – Hygienic, non-toxic, and food-grade compliant

🚗 Automotive & Manufacturing – Durable, oil-resistant, and abrasion-resistant

📦 Logistics & Warehousing – Lightweight, energy-efficient, and highly flexible

🩺 Pharmaceutical & Medical – Easy to clean, non-contaminating, and high-precision

🏗 Construction & Heavy Industry – High wear resistance and durability

5. Environmental and Sustainability Impact

When evaluating conveyor belt materials, environmental impact is becoming increasingly important:

- Reduced Waste: TPU belts’ longer lifespan leads to fewer replacements and less waste.

- Energy Efficiency: Lower operational energy consumption contributes to smaller carbon footprint.

- Recyclability: Many TPU belt formulations are recyclable, contributing to circular material strategies.

- Reduced Harmful Emissions: TPU incineration produces fewer toxic emissions than some rubber-based alternatives.

6. Conclusion

If you’re looking for a long-lasting, energy-efficient, and cost-effective conveyor belt solution, TPU belts are the best choice over traditional PVC and rubber belts.

At PENGDE NEW MATERIAL TECHNOLOGY CO., LTD, we specialize in high-quality TPU conveyor belts tailored to meet your industry’s unique needs. Contact us today at pengde2@pengde-pu.com to explore custom TPU belt solutions for your business!