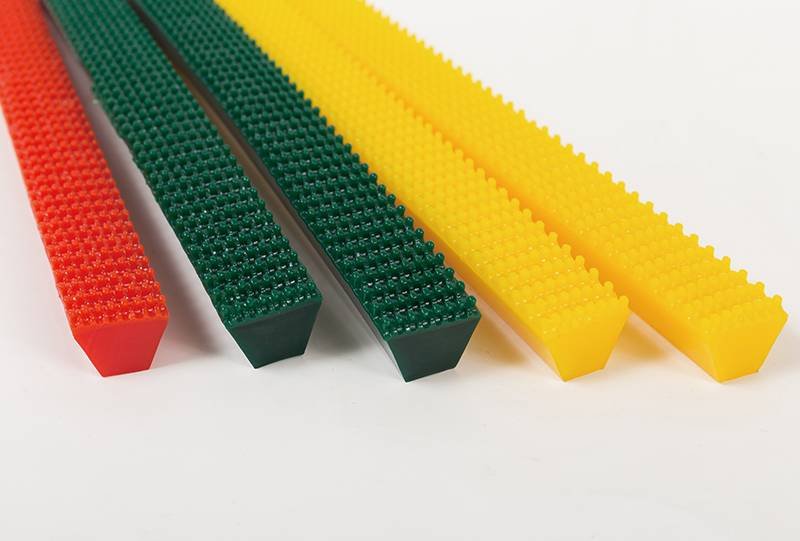

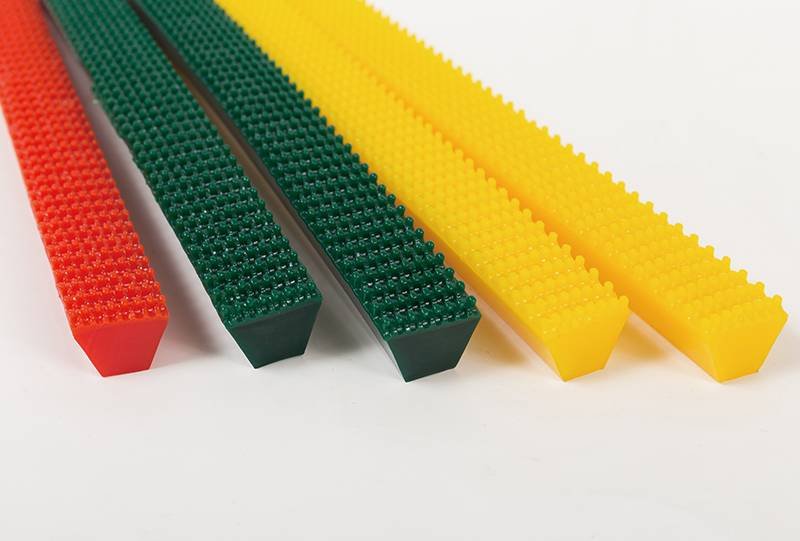

TPU stands for Thermoplastic polyurethane and it is a melt-kneading flame-retardant polymer that is docile and long-lasting. When it comes to Thermoplastic polyurethane offers a good number of chemical and physical properties for its uses. TPU material can be used in different sectors like in the non-yellowing companies, automobile sector, sports and textile etc. this polymer comes with the features of rubber and plastics because of its flame-retardant nature, it is non-flammable. This is why its material offers a lot more benefits than other polymers. The information is detailed below.

Features of TPU Material

This polymer comes with different features or properties that are why it can be used in different ways. So what are their features?

Abrasion support: it has the property to support Abrasion as it will retain its physical look in the face of scrapes or scratches.

Resisting Liquid: Thermoplastic polyurethane cannot mix with stains or oil, it resists them that is why it has a unique look as it retains its looks while keeping things from liquids.

Strong load capacity: It has the power to withstand heavy loads placed on it, as it has the capacity to bear heavy loads.

Flexibility: TPU material is malleable as it can easily imbibe any impacts or shocks.

High power: TPU material has the most strength than other polymers in the market. The strength of this material is quite high. So bending it in a normal way will be difficult. It will take a lot more pressure to be able to bend any TPU material.

How is TPU material manufactured?

Thermoplastic polyurethane material is produced from the interaction of polycarbonate-based or polyester polyether known as polyols, short-chain dios and di-isocyanate. With this reaction, additives can also be thrown into the mix to get special properties. When all these substances have been mixed, it will result in mechanical properties with a large range of hardness.

Then again, Thermoplastic polyurethane material can also come in an optional soft and hard sequence or segments. This will help it adjust easily when manipulated. When this material is adjusted it can result in diverse hardness. The truth is that the harder a TPU segment is, the stiffer it becomes.

Benefits of TPU material

High application needs: The TPU material is used in diverse ways and is great for different industrial companies. It can be used as a sealant, for coating and manufacturing footwear, leather and others.

Cost-effective: TPU material is long-lasting as it doesn’t have phenol, a kind of chemical added to rubbers. So it is easy to process and the production cost is reduced. When it comes to colouring, simple pigments can be used. So producing it is a lot cheaper.

TPU material can be recycled: This material can be recycled and you wouldn’t need to use high energy to achieve this.

TPU material is needed in different areas of life as they are used for different purposes. It is one Thermoplastics that is in high demand because of its versatility and flexibility.

For further questions, please contact us at pengde2@pengde-pu.com.