Quick Answer

A screen printing squeegee is one of the most critical tools in achieving uniform ink transfer and high-quality prints. The most popular materials for squeegees are Polyurethane (PU), Neoprene, and Rubber. Each material has different properties, durability, and cost, making it essential to choose based on your printing process, substrate, and ink type.

What is a Screen Printing Squeegee?

A squeegee is a rubber or polymer tool used in screen printing to push ink through the mesh onto the printing substrate. Its condition, material, and design significantly affect print quality. A dull or damaged squeegee can cause uneven ink distribution, streaks, or incomplete prints.

Squeegees are used across textile printing, glass printing, electronics, packaging, and many other industries. Understanding material differences is crucial to maximizing print consistency, longevity, and efficiency.

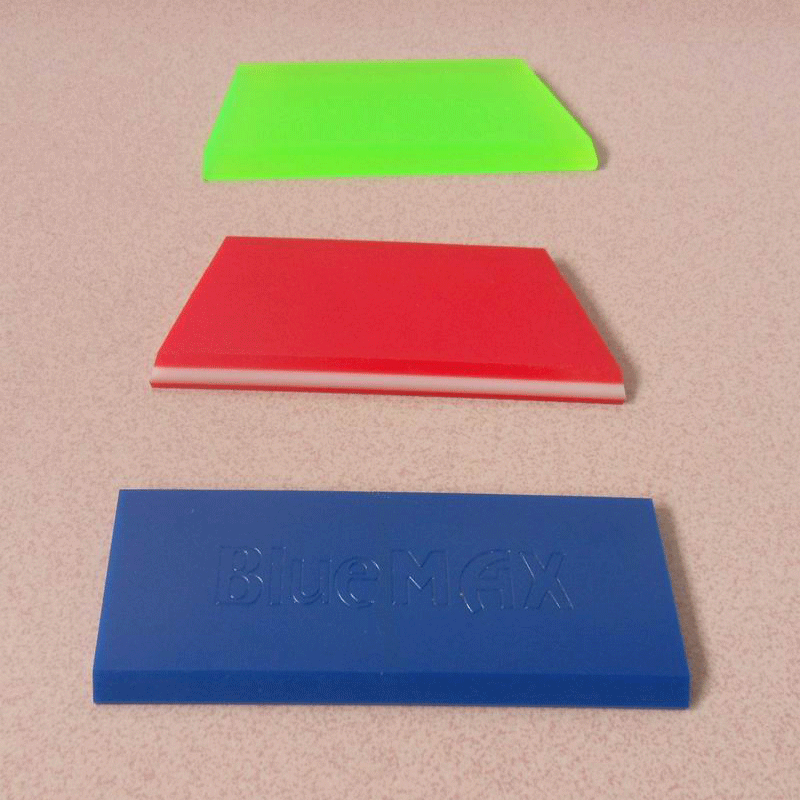

Materials Used for Squeegees

1. Rubber Squeegees

- Advantages: Low cost, easy to manufacture, flexible, suitable for educational or hobbyist printing.

- Limitations: Poor abrasion resistance, low chemical resistance, shorter lifespan, prone to damage in heavy-duty applications.

Rubber squeegees are still common in low-demand environments but often fail in semi-automatic or industrial processes.

2. Neoprene Squeegees

- Advantages: Synthetic rubber with better abrasion and chemical resistance than natural rubber.

- Limitations: Higher cost than rubber, less durable than PU.

Neoprene is a middle ground—ideal for small-batch printing or moderate chemical exposure.

3. Polyurethane (PU) Squeegees

- Advantages: Excellent abrasion and chemical resistance, long-lasting, high load tolerance, versatile for semi-automatic and automatic processes.

- Limitations: Higher upfront cost, slightly stiffer feel in some applications.

The most widely used PU material for squeegees is MDI-based polyester, known for exceptional durability and performance in high-speed printing environments.

Squeegee Size and Hardness Selection

Choosing the right size and hardness is essential for optimal ink transfer:

- Common Sizes:

- 3/8″ x 2″ PU Squeegee: Standard for textiles, glass, and electronics.

- 3/16″ x 1″ PU Squeegee: Suitable for bottles and automated high-speed processes.

- Hardness (Shore A):

- 70A–75A: Soft, ideal for fine details or delicate substrates.

- 80A–90A: Medium, versatile for most screen printing processes.

- 95A+: Hard, best for thick inks or abrasive surfaces.

Matching size and hardness to your material and ink ensures consistent coverage, reduces wear, and extends squeegee life.

Comparison Table: PU vs Neoprene vs Rubber

| Material | Abrasion Resistance | Chemical Resistance | Lifespan | Cost | Best Use Case |

|---|---|---|---|---|---|

| PU | Excellent | Excellent | 2–3x rubber | High | Semi-automatic/automatic processes, heavy-duty use |

| Neoprene | Good | Good | Medium | Medium | Small-batch, moderate chemical exposure |

| Rubber | Poor | Poor | Low | Low | Hobby, educational, low-stress applications |

How to Choose the Right Squeegee for Your Process

Follow these steps to select the optimal squeegee:

- Assess your printing environment – Manual, semi-automatic, or automatic printing.

- Consider ink type and substrate – Thick or abrasive inks require harder PU squeegees.

- Decide on size and hardness – Refer to the chart above.

- Factor in budget vs. longevity – PU squeegees cost more upfront but last 2–3x longer, reducing replacement costs.

- Test and adjust – Small trials ensure optimal performance for your specific application.

FAQ

Q1: Can PU squeegees be used for high-speed automatic printing?

A: Yes, PU squeegees are highly durable and suitable for semi-automatic and fully automated screen printing processes.

Q2: How long does a PU squeegee last compared to rubber?

A: Typically, PU squeegees last 2–3 times longer than rubber under similar conditions.

Q3: What is the best hardness for general screen printing?

A: Medium hardness (80A–90A) is ideal for most substrates and inks.

Q4: Can neoprene replace PU in industrial applications?

A: Neoprene is suitable for moderate chemical exposure and small-batch printing but cannot match PU’s abrasion resistance and lifespan for heavy-duty use.

Conclusion

Selecting the right squeegee is crucial for print quality, durability, and operational efficiency. Polyurethane (PU) squeegees stand out for industrial and high-speed printing due to their superior abrasion and chemical resistance. Neoprene offers a mid-tier alternative, while rubber remains suitable for hobbyist and educational purposes.

Investing in the correct material, size, and hardness ensures consistent prints, longer tool life, and reduced downtime.

Contact PENGDE:

For high-quality PU squeegees and customized solutions, reach out at pengde2@pengde-pu.com.