Polyurethane Plate

Polyurethane Plate

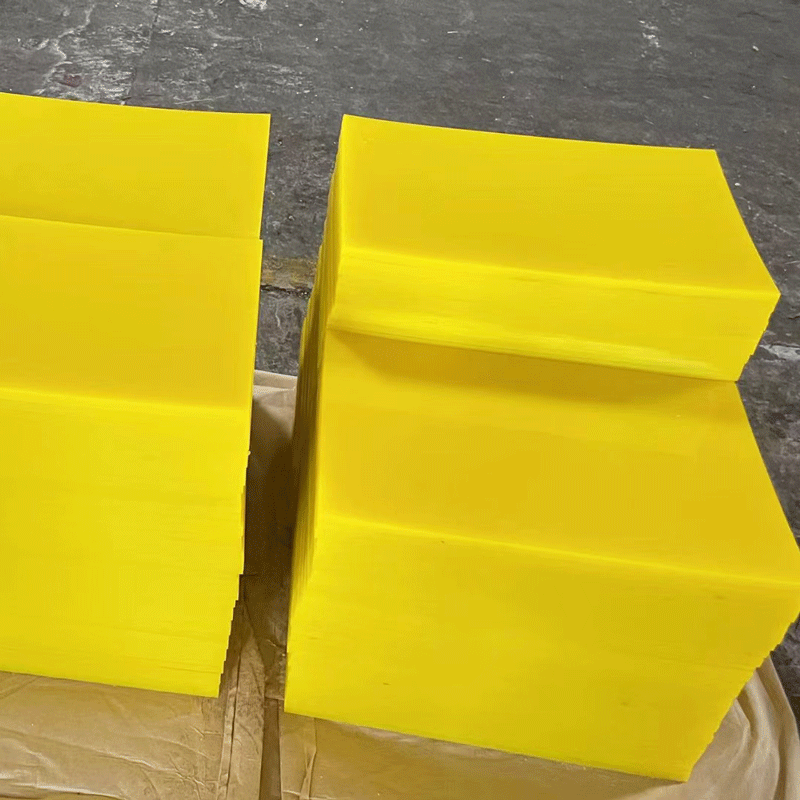

Polyurethane plate is a solid, high-strength elastomer material designed for industrial applications that require superior wear resistance, load-bearing capability, and impact absorption. Compared with thinner polyurethane sheets, PU plates are typically used where material thickness and structural stability are critical.

Product Specifications

- Material: Polyurethane elastomer

- Form: Solid plate

- Thickness Range: Medium to thick plates, customizable

- Standard Sizes: Available, custom sizes supported

- Hardness Range: Multiple Shore A grades

- Density: Uniform and stable

- Surface Finish: Smooth or machined

- Color Options: Standard or customized

Key Features

- Exceptional Abrasion Resistance

Ideal for high-wear and sliding contact applications - High Load-Bearing Capacity

Maintains shape and performance under continuous pressure - Excellent Impact and Shock Absorption

Protects equipment and reduces vibration - Tear and Compression Resistance

Suitable for heavy-duty industrial use - Machinable and Fabrication-Friendly

Can be cut, drilled, and CNC machined into complex parts - Long Service Life

Reduces downtime and replacement frequency

Applications

- Industrial wear plates and liners

- Equipment support and buffer plates

- Conveyor and material handling systems

- Machinery base pads and protective layers

- Mining, ceramics, and heavy equipment components

- Custom polyurethane machined parts

Customization & Manufacturing Support

- Custom plate thickness and dimensions

- Hardness selection based on working load

- Material formulation adjustments

- Support for drawings, samples, and OEM projects

- Stable production for batch and long-term supply

Frequently Asked Questions

Q1: How is a polyurethane plate different from a polyurethane sheet?

Polyurethane plates are thicker and designed for load-bearing and heavy-duty applications, while sheets are thinner and more flexible.

Q2: Can polyurethane plates replace metal or plastic wear plates?

In many applications, polyurethane plates offer better wear resistance and impact absorption than metal or rigid plastics.

Q3: Are polyurethane plates suitable for machining?

Yes, they can be machined using standard cutting and CNC processes.

Q4: What hardness options are available?

Multiple hardness grades are available to match different load and wear conditions.

Q5: Can polyurethane plates be customized for specific equipment?

Yes, customization based on drawings or samples is supported.