Timing Belt Conveyors

Timing Belt Conveyors

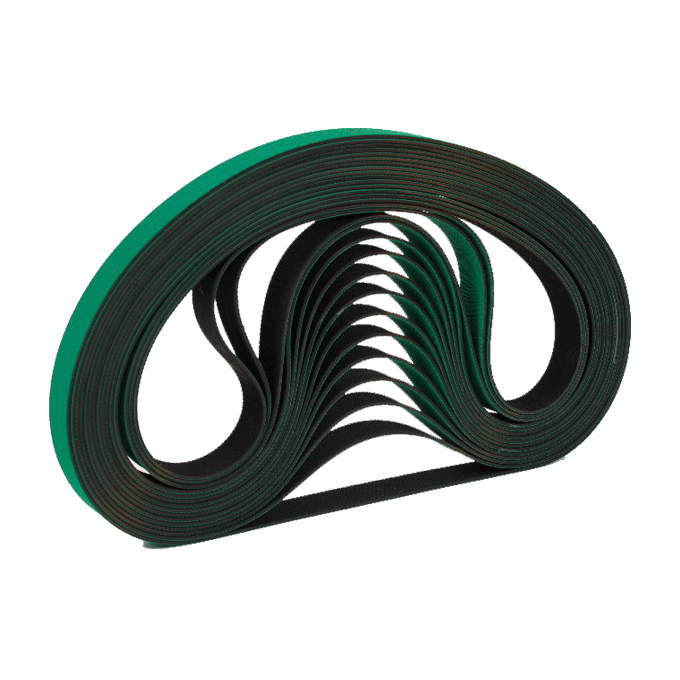

Timing belt conveyors are industrial conveyor systems that use toothed polyurethane (PU) belts to provide precise, synchronized movement of materials. These systems ensure accurate positioning and reliable handling of products on automated production lines, packaging equipment, and assembly lines.

Specifications

- Conveyor Type: Timing belt conveyor (toothed belt system)

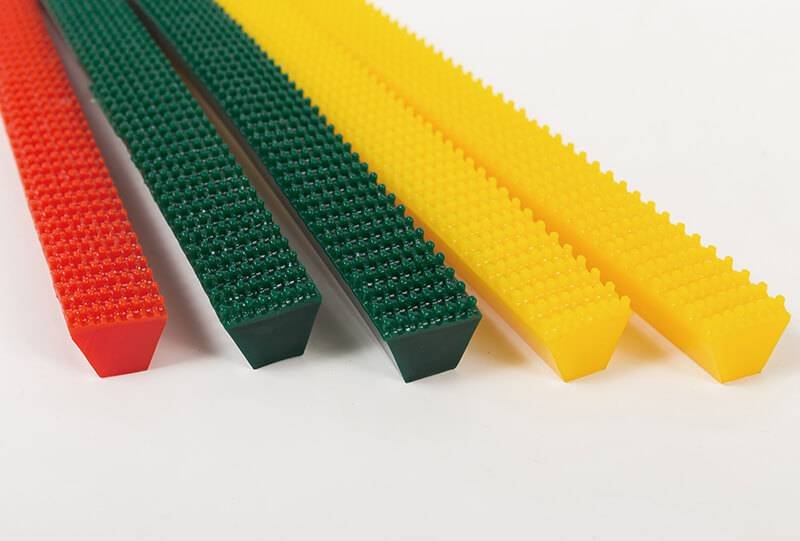

- Belt Material: Polyurethane (PU) with embedded tensile cords

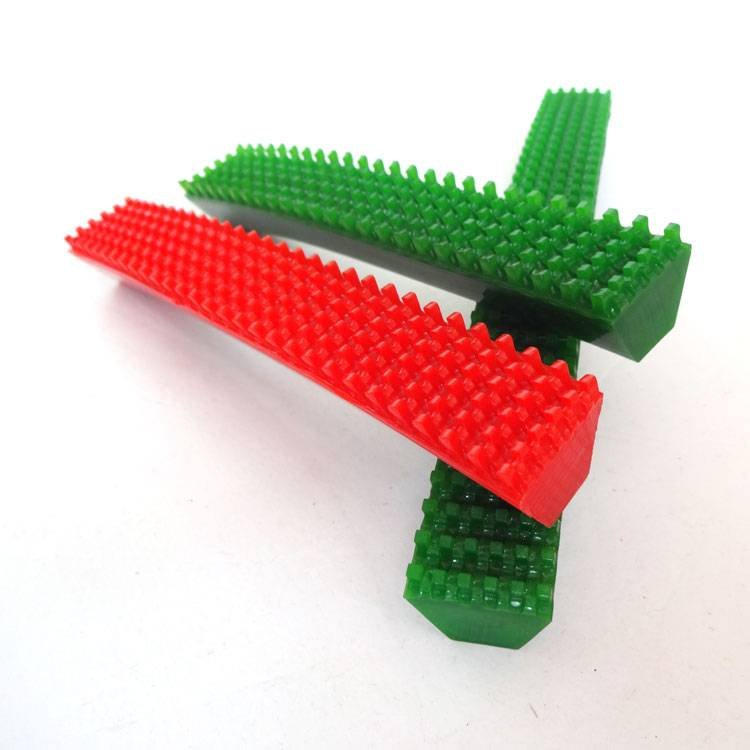

- Tooth Type: Standard trapezoidal or custom profile

- Width: Customizable

- Length: Customizable

- Belt Thickness: Options available depending on load

- Tensile Strength: High load capacity

- Operating Temperature: Suitable for industrial environments

- Drive Method: Motor-driven pulley system

- Optional Features: Side guards, guides, support rollers

Key Features & Advantages

- Synchronized Material Handling

Prevents slippage and ensures precise positioning - High Wear Resistance

PU construction withstands long-term industrial use - Customizable Design

Belt width, length, and tooth profile can be tailored to specific applications - Low Maintenance

Reliable operation with minimal downtime - Smooth & Quiet Operation

Polyurethane timing belts reduce noise and vibration - Versatile Industrial Applications

Works in packaging, electronics assembly, food processing, and logistics lines

Typical Applications

- Automated production lines

- Packaging and bottling machines

- Electronics assembly conveyors

- Food and beverage processing lines

- Logistics and distribution centers

- Precision manufacturing assembly

Customization & OEM Services

- Custom belt width, length, and tooth pitch

- Special PU formulations for chemical or high-temperature environments

- Custom conveyor frame designs for specific applications

- OEM branding and bulk supply options

FAQ

Q1: What is a timing belt conveyor?

It is a conveyor system that uses toothed PU belts to move products synchronously, preventing slippage and ensuring precise positioning.

Q2: Why use polyurethane timing belts?

PU belts offer high wear resistance, flexibility, and longer service life compared to rubber, while maintaining precise tooth engagement.

Q3: Can I customize the belt size and tooth profile?

Yes, width, length, thickness, and tooth type can all be customized to fit your application.

Q4: What industries commonly use timing belt conveyors?

They are widely used in automated assembly, packaging, electronics, food processing, and logistics systems.

Q5: How does it differ from a standard conveyor belt?

Unlike flat belts, timing belts have teeth that engage with pulleys, providing accurate and synchronized movement without slippage.