Thermoplastic Polyurethane is one plastic polymer material that is easily moldable at some high temperatures. When it is left to cool it becomes solid, it has elastic tendencies since it is just like rubber. TPU can be processed by compression, injection or even via extrusion. It can be used in our daily life to produce and create different just like any polymer out there it has advantages that are unique to its kind. Below are the advantages of Thermoplastic Polyurethane

The truth is that every product comes with two sides, the good and the bad sides but with impactful products, the advantages far outweigh their disadvantages. It can be said to be a perfect product with the below advantages.

Thermoplastic Polyurethane can be said to be solution coated as it is used in different areas of life. It is more like thermoforming; where plastic is formed into permanent items. It is ideal for different production, creation, technique or procedure.

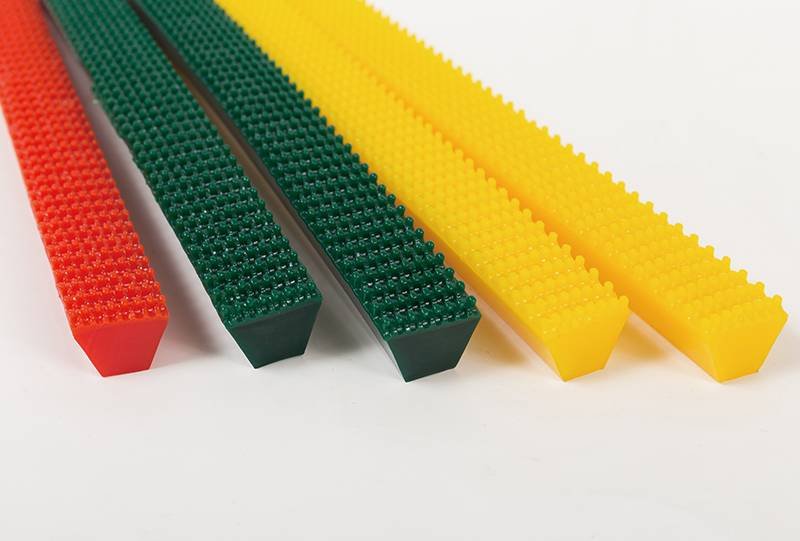

Colouring is easy with Thermoplastic Polyurethane

Unlike other thermoplastic polymers, Thermoplastic Polyurethane can easily be coloured. Though it has to undergo a lot more processes to get it right with its colouring, the result is always better and preferable to others.

Versatility at its best

TPU is very versatile as it has a good number of physical properties making it easily adaptable to different applications. The products from Thermoplastic Polyurethane are very adjustable; this is because TPU has a combination of both the soft and hard segments.

The exhibition of hard segment comes as either a fragrant or an organic compound while the soft segment will either come as polyester or polyether.

Non-use Plasticizer

There’s no use of Plasticizer in Thermoplastic Polyurethane. TPU doesn’t need any substance to be added to it either to make it flexible or soften it. This polymer naturally comes as plastics or rubbers. So no need for substance addition to either increase its thickness or decrease its malleability. This simply means that it can be used as a soft engineering material or a very hard rubber, unlike other polymers.

Ease of processing

With Thermoplastic Polyurethane processing it is very easy. It is easy to get it sterilized from bacteria and other microorganisms. Processes like melting its parts together to bring fusion, creating aesthetic qualities, casting impressions on it and even using dye on it are easily done.

It is biocompatible

Thermoplastic Polyurethane responds favourably all the time to its host when applied. This is because it operates on low-temperature flexibility. It doesn’t easily dissolve but is stable and also fire retardant.

Resistance to impacts

One good thing about Thermoplastic Polyurethane is its high level of resilience. It can withstand external pressure like bad atmospheric conditions, hydrocarbons, and any friction or compression. It is structured in an outstanding way to live above the high impacts on it.

The above-outlined advantages of Thermoplastic Polyurethane show that this material is very versatile and can be used in diverse ways.

For further questions, please contact us at pengde2@pengde-pu.com.