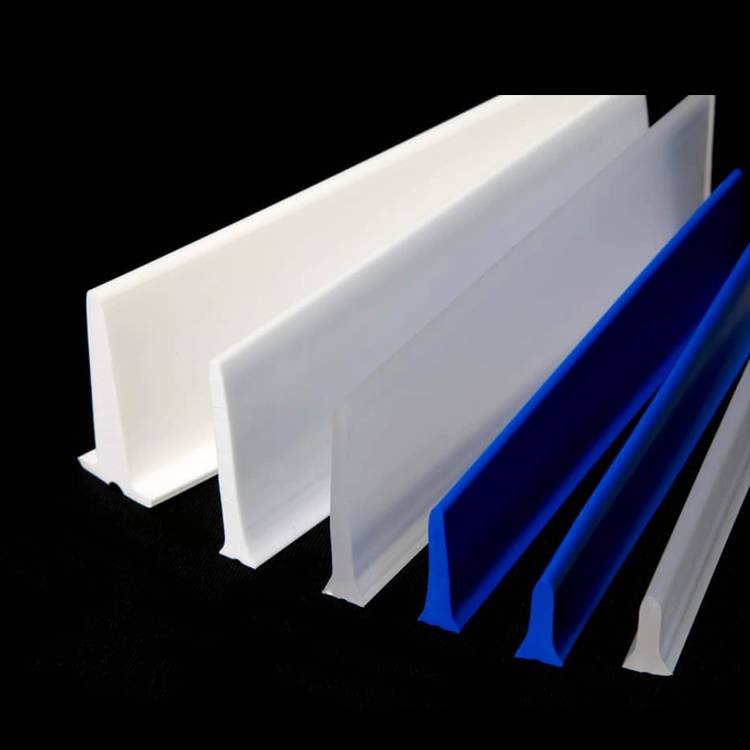

Polyurethane Blades

Polyurethane Blades

Our polyurethane blades are engineered for precision scraping, coating, and material handling in industrial applications. Made from high-quality PU, these blades combine excellent wear resistance, chemical resistance, and elasticity to deliver consistent performance even in demanding environments.

Specifications

- Material: Polyurethane (PU)

- Blade Type: Scraper, squeegee, cutting blade

- Dimensions: Custom length, width, thickness

- Hardness: Multiple Shore A options

- Edge Style: Straight, beveled, or custom

- Color: Standard (black, white, transparent) or custom

- Temperature Range: Industrial standard (-20°C to 80°C)

- Chemical Resistance: Resistant to oils, inks, coatings, and mild acids

Key Features & Performance Advantages

- High Wear & Abrasion Resistance

Long-lasting performance on industrial production lines - Elastic & Shock Absorbing

Protects surfaces and reduces material damage - Chemical & Oil Resistant

Suitable for food, printing, packaging, and ceramic environments - Customizable Sizes & Edge Profiles

Tailored for specific machinery and applications - Consistent Performance

Ensures uniform scraping, coating, or material transfer - Low Maintenance & Long Service Life

Reduces downtime and replacement frequency

Applications

- Printing and screen printing squeegees

- Ceramic and glass production lines

- Food processing and packaging machinery

- Coating and laminating equipment

- OEM replacement PU blades

- Industrial scraping and material handling operations

Customization & Supply Options

- Custom length, width, thickness, and edge profiles

- Hardness tailored to application needs

- Small-batch prototyping and bulk production

- OEM and aftermarket solutions

FAQ

Q1: What are polyurethane blades used for?

They are used for scraping, coating, cutting, or transferring materials in industrial production processes.

Q2: Can PU blades be customized?

Yes, length, width, thickness, hardness, and edge profile can all be customized for your equipment.

Q3: Why choose PU blades over metal or rubber blades?

Polyurethane offers better wear resistance, elasticity, chemical resistance, and reduces surface damage.

Q4: Which industries commonly use PU blades?

Printing, ceramics, glass, food processing, packaging, and OEM machinery widely use polyurethane blades.

Q5: Are these blades resistant to chemicals and oils?

Yes, they withstand inks, coatings, oils, and mild industrial chemicals.