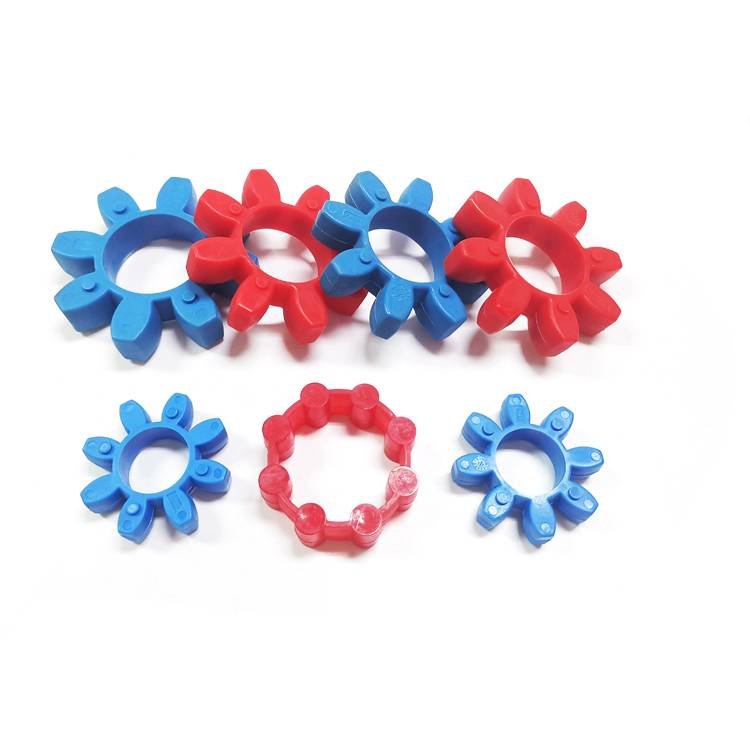

Polyurethane Coupling

Polyurethane Coupling

Our polyurethane couplings are engineered to provide reliable torque transmission while reducing vibration, shock, and noise in industrial drive systems. Manufactured from high-quality PU material, these couplings combine flexibility with durability, making them an ideal alternative to traditional rubber or metal couplings.

Specifications

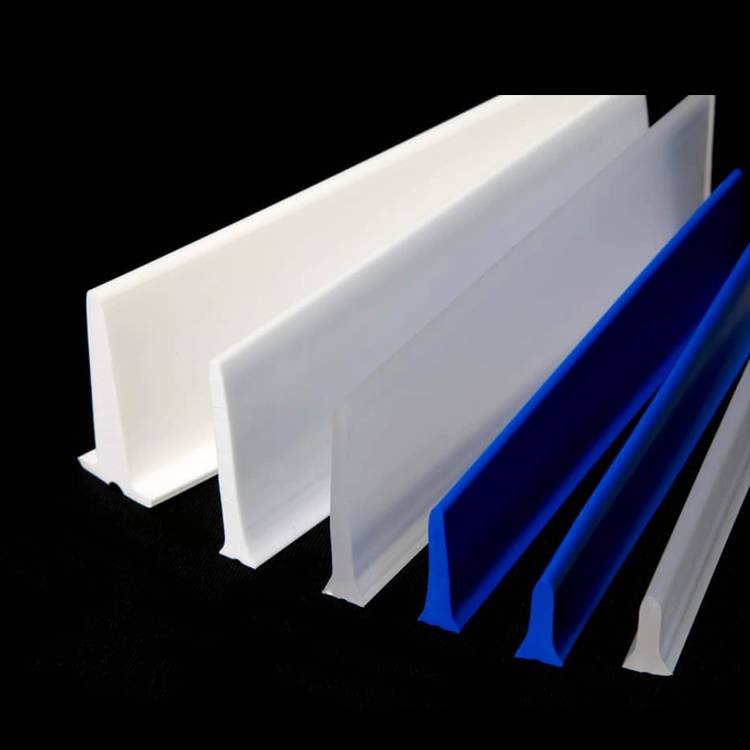

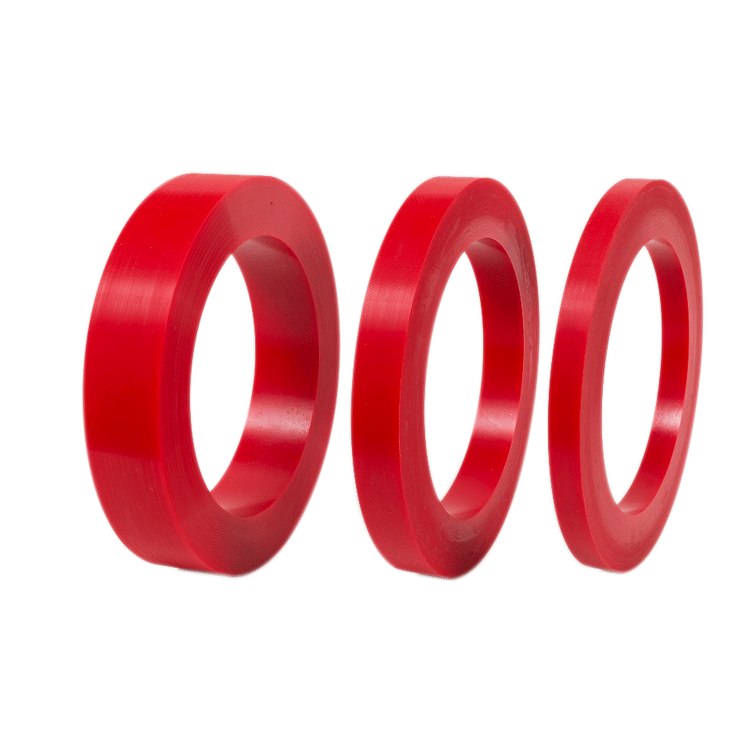

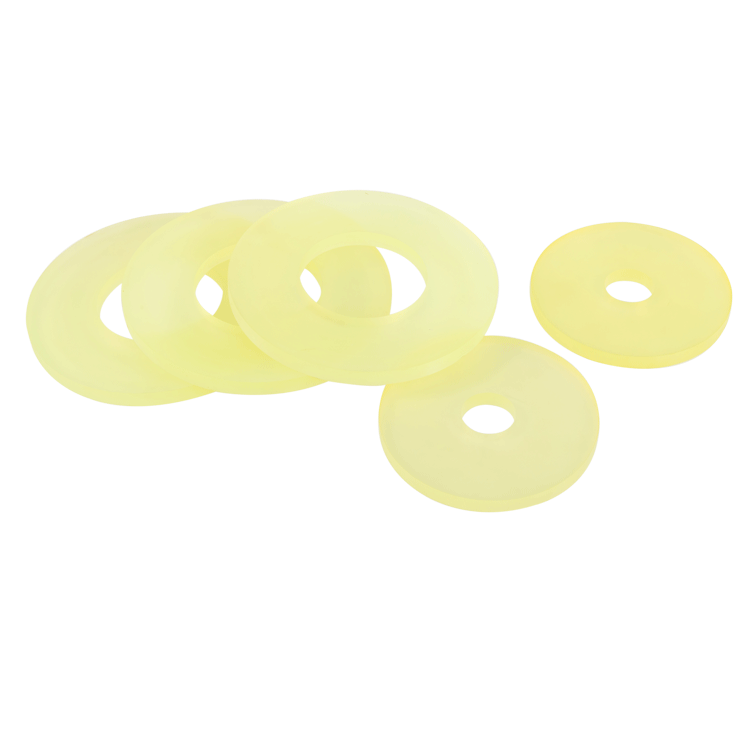

- Material: Polyurethane (PU)

- Coupling Type: Flexible coupling / jaw coupling insert / PU spider

- Torque Transmission: Designed for industrial drive systems

- Hardness: Multiple Shore A options

- Operating Temperature: Suitable for typical industrial environments

- Wear Resistance: Excellent abrasion resistance

- Chemical Resistance: Resistant to oil, grease, and mild chemicals

- Compatibility: Suitable for common coupling hubs and systems

Key Features

- Excellent Vibration & Shock Absorption

Reduces load impact on motors and gearboxes - Flexible Torque Transmission

Compensates for angular and parallel misalignment - High Wear & Fatigue Resistance

Longer service life compared to rubber couplings - Oil & Chemical Resistant

Performs reliably in harsh industrial environments - Quiet Operation

Reduces noise during equipment operation - Customizable Hardness & Design

Tailored to torque and speed requirements

Applications

- Motor and gearbox connections

- Pumps and compressors

- Conveyor drive systems

- Packaging and processing machinery

- Industrial automation equipment

- OEM mechanical drive assemblies

Customization & Supply Capability

- PU coupling inserts manufactured to drawings or samples

- Custom hardness to match torque and damping needs

- Replacement parts compatible with standard coupling hubs

- Support for prototypes, small batches, and mass production

FAQ

Q1: What is a polyurethane coupling used for?

It transmits torque between shafts while absorbing vibration and shock to protect equipment.

Q2: Why choose PU couplings over rubber couplings?

PU couplings offer better wear resistance, longer service life, and improved chemical resistance.

Q3: Can polyurethane couplings handle misalignment?

Yes, they are designed to compensate for angular and parallel shaft misalignment.

Q4: Are PU couplings suitable for high-speed applications?

Yes, when properly selected, they perform reliably in various speed and load conditions.

Q5: Do you provide custom polyurethane couplings?

Yes, we offer custom PU coupling components based on drawings or application requirements.