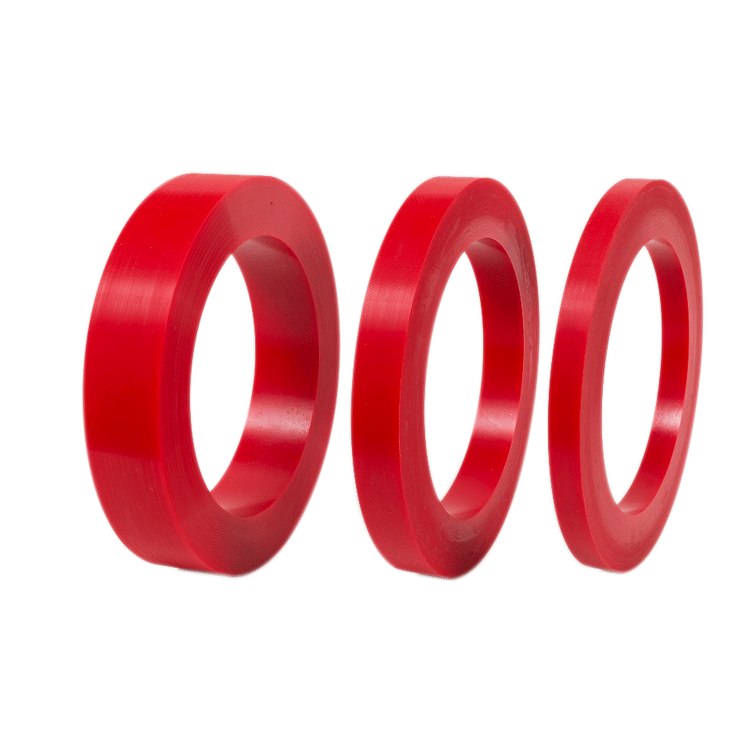

Polyurethane Seal

Polyurethane Seal

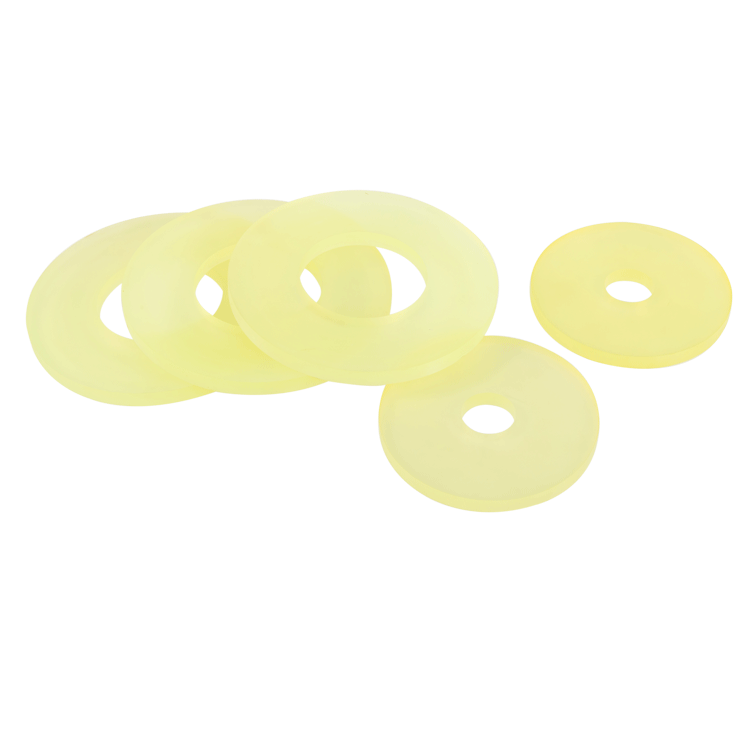

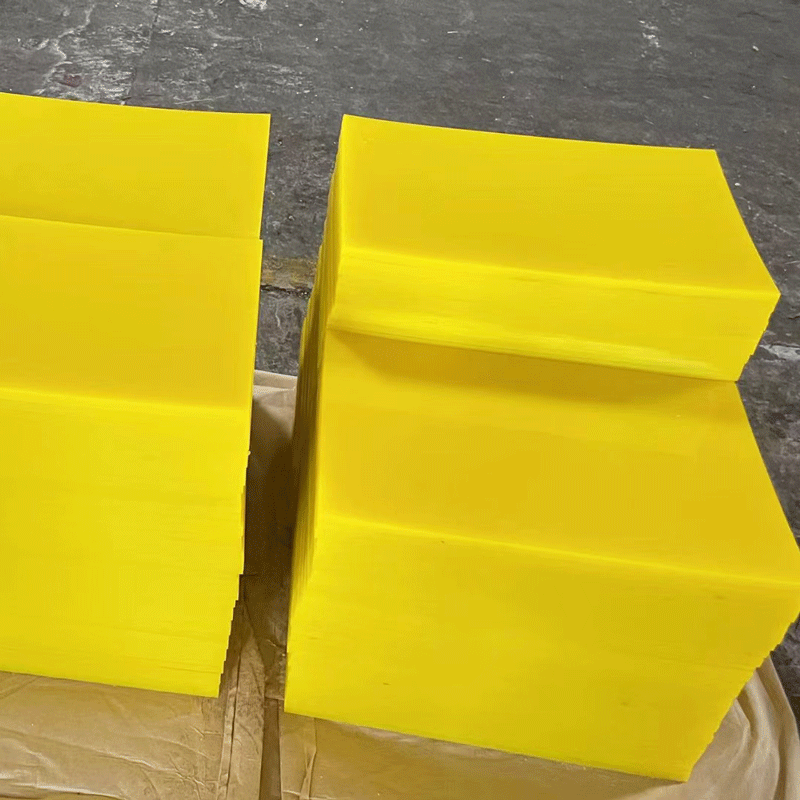

Polyurethane seals are precision-engineered elastomeric components designed to provide reliable sealing in demanding industrial applications. Made from premium PU materials, these seals offer superior wear resistance, elasticity, and chemical stability compared to traditional rubber seals.

Specifications

- Material: Polyurethane elastomer

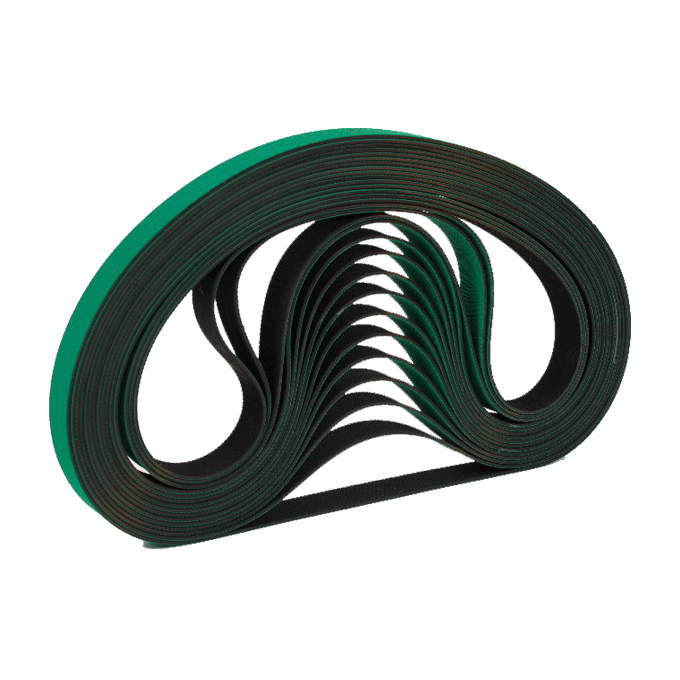

- Seal Types: O-ring, U-cup, V-ring, custom profiles

- Hardness: Multiple Shore A grades

- Dimensions: Customizable diameter, width, and thickness

- Temperature Range: Suitable for industrial operating conditions

- Chemical Resistance: Oil, water, and common industrial chemicals

- Color Options: Standard or custom

- Surface Finish: Smooth or textured as required

Key Features

- Superior Wear Resistance

Maintains seal integrity over extended operating periods - High Compression & Elasticity

Ensures tight sealing under pressure and dynamic loads - Chemical & Oil Resistance

Reliable performance in harsh industrial fluids and chemicals - Temperature Stability

Performs under elevated or fluctuating temperatures - Customizable Dimensions & Profiles

Supports OEM and specialized applications - Long Service Life

Reduces maintenance frequency and operational downtime

Applications

- Hydraulic and pneumatic cylinders

- Pumps, valves, and compressors

- Mechanical shafts and rotating equipment

- OEM replacement seals for industrial machinery

- Sealing solutions for automation equipment

- Wear-resistant sealing in material handling systems

Customization & OEM Support

- Custom dimensions, shapes, and hardness options

- Material formulation optimized for specific pressure and chemical environments

- Support for drawings, samples, and prototype testing

- Long-term supply for OEM and industrial projects

FAQ

Q1: How does a polyurethane seal differ from a standard rubber seal?

PU seals offer higher wear resistance, better elasticity, chemical resistance, and longer service life than standard rubber seals.

Q2: Can polyurethane seals be customized?

Yes, all dimensions, hardness, and shapes can be customized according to your application requirements.

Q3: Are PU seals suitable for high-pressure hydraulic applications?

Yes, they maintain sealing integrity under high pressure and dynamic operating conditions.

Q4: What types of polyurethane seals are available?

Common types include O-rings, U-cups, V-rings, and custom profiles tailored to equipment needs.

Q5: Can these seals be used in OEM machinery replacements?

Yes, we provide custom PU seals for OEM machinery and industrial equipment.