Polyurethane Wear Liners

Polyurethane Wear Liners

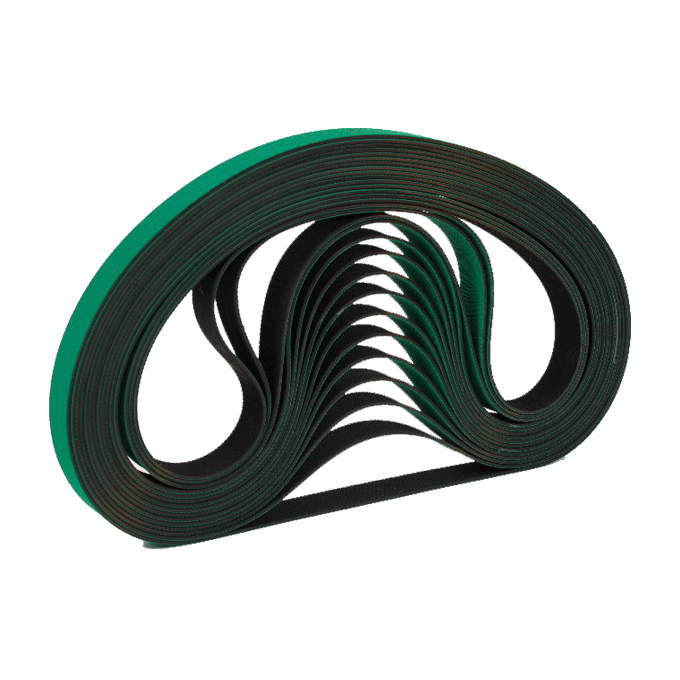

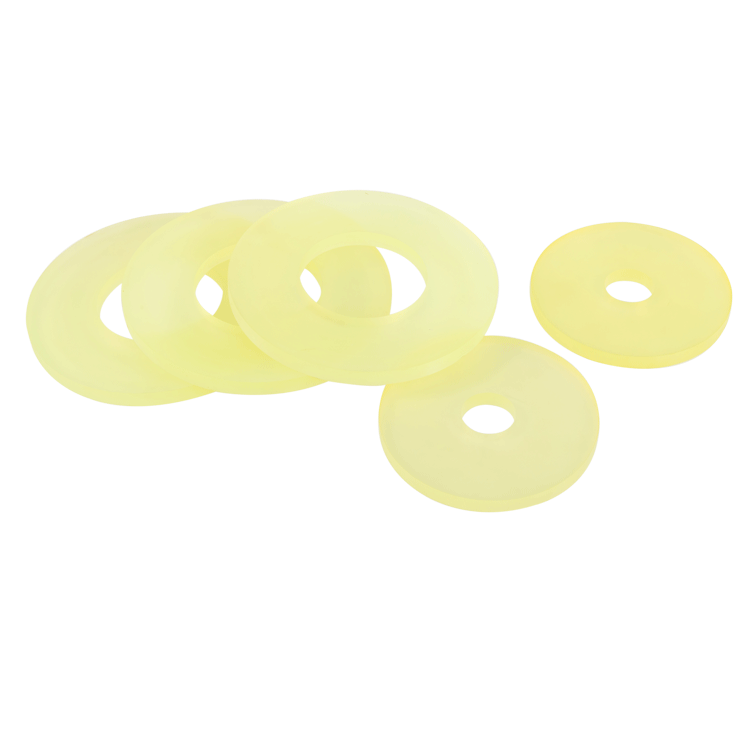

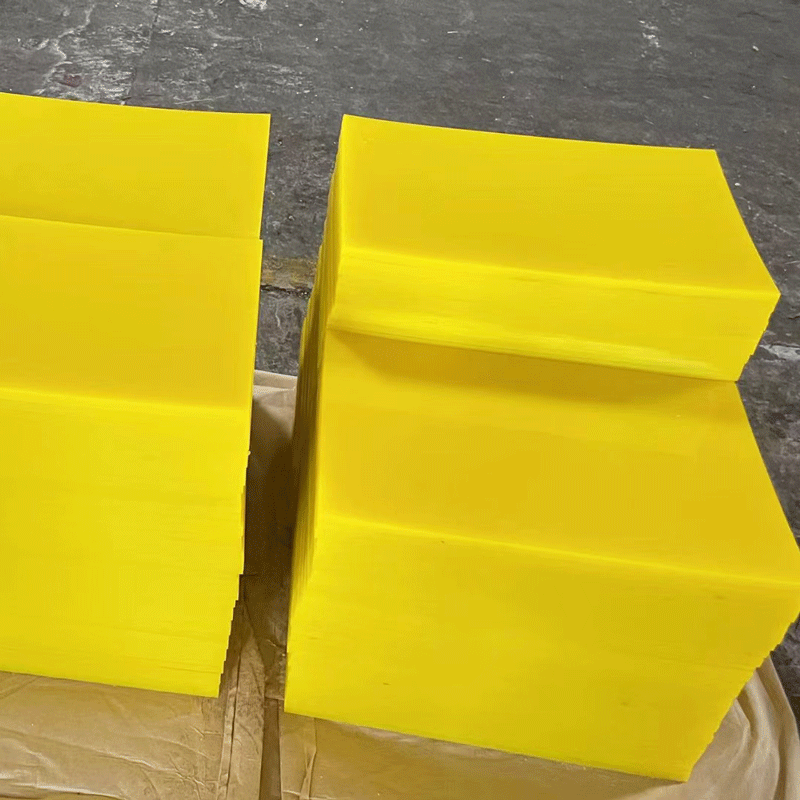

Polyurethane wear liners are high-performance protective lining solutions engineered to withstand severe abrasion, impact, and continuous material flow in industrial environments. Manufactured from premium polyurethane elastomer, these liners provide superior wear resistance, noise reduction, and long service life compared to traditional steel or rubber liners.

Product Specifications

- Material: High-performance polyurethane (PU) elastomer

- Standard Thickness Range: Customizable (thin to heavy-duty grades)

- Sheet Size: Custom cut or molded panels

- Hardness Options: Multiple Shore A grades available

- Color Options: Standard or custom colors

- Surface Type: Smooth, textured, or patterned

- Mounting Options: Bolt-on, adhesive bonding, or embedded fixing systems

- Operating Temperature Range: Suitable for various industrial environments

Key Features & Performance Advantages

- Exceptional Abrasion Resistance

Significantly longer service life than rubber and steel liners - High Impact Strength

Absorbs shock from heavy material flow and reduces equipment damage - Noise & Vibration Reduction

Quieter operation compared to metal liners - Lightweight yet Strong

Easier installation without sacrificing durability - Chemical & Moisture Resistant

Performs reliably in wet and corrosive environments - Customizable for Equipment Geometry

Designed to fit conveyors, chutes, hoppers, and transfer points

Typical Applications

- Conveyor systems and transfer points

- Material chutes and hoppers

- Mining and quarry equipment

- Cement and aggregate processing plants

- Steel and metallurgical industries

- Ceramic and bulk material handling machinery

- Truck beds and loading zones

Customization & OEM Capabilities

- Custom liner sizes, shapes, and thicknesses

- Hardness selection based on wear and impact conditions

- Pre-drilled holes and molded mounting systems

- Bonded metal backing options (if required)

- Engineering support for complex wear protection projects

FAQ

Q1: What are polyurethane wear liners used for?

They protect industrial equipment surfaces from abrasion, impact, and material flow damage.

Q2: Are PU wear liners better than rubber or steel liners?

Yes, they offer longer wear life than rubber and better impact absorption than steel in many applications.

Q3: Can wear liners be customized?

Absolutely. Thickness, size, hardness, and mounting methods can all be tailored.

Q4: Are polyurethane liners suitable for wet environments?

Yes, they are moisture-resistant and perform well in damp and corrosive conditions.

Q5: How do I choose the right liner thickness and hardness?

Our technical team can recommend specifications based on material type, impact level, and operating conditions.