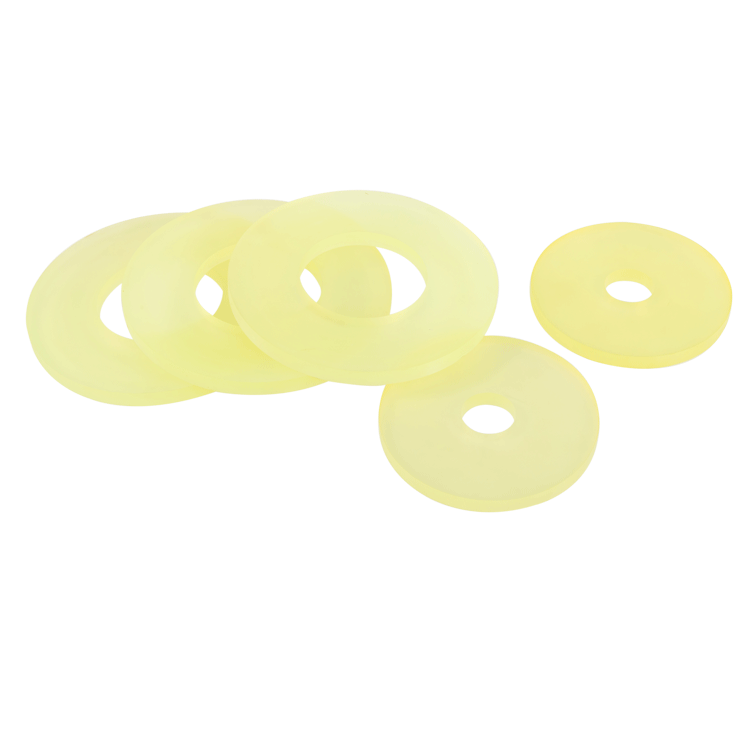

PU O-Ring

PU O-Ring

PU O-rings are precision-engineered sealing components made from premium polyurethane elastomer. Designed for demanding industrial, hydraulic, and pneumatic applications, these O-rings provide excellent wear resistance, elasticity, and chemical stability. They are ideal for sealing, cushioning, and vibration damping in machinery and equipment, outperforming traditional rubber or metal O-rings in many applications.

Specifications

- Material: High-quality polyurethane (PU) elastomer

- Form: O-ring / sealing ring

- Inner Diameter (ID): Customizable

- Outer Diameter (OD): Customizable

- Cross-Section / Thickness: Customizable

- Hardness: Multiple Shore A grades available

- Color Options: Standard or custom

- Resistance: Wear, abrasion, chemical, oil, and impact resistant

- Temperature Range: Suitable for hydraulic, pneumatic, and industrial applications

Key Features & Advantages

- Excellent Wear & Abrasion Resistance

Ensures long-lasting sealing performance under repetitive motion - Superior Elasticity & Compression Recovery

Maintains tight seals under pressure and mechanical stress - Chemical & Oil Resistance

Performs reliably in hydraulic fluids, oils, and industrial chemicals - Customizable Dimensions & Hardness

Tailored for OEM machinery, hydraulic systems, or industrial equipment - Durable & Long-Lasting

Reduces maintenance frequency and equipment downtime - Easy Replacement & Installation

Compatible with standard or custom machinery components

Typical Applications

- Hydraulic and pneumatic cylinders

- Industrial machinery and equipment seals

- Automotive and aerospace applications

- OEM replacement for machinery and mechanical assemblies

- Vibration and leakage prevention in moving parts

- Fluid transfer systems and pressurized equipment

Customization & OEM Support

- Custom inner diameter, outer diameter, cross-section, and hardness

- Color options for visual identification or coding

- Small-batch and large-scale OEM production

- Technical support for material selection, design, and performance optimization

FAQ

Q1: What are PU O-rings used for?

They are used as sealing components in hydraulic, pneumatic, and industrial applications to prevent leaks and maintain pressure.

Q2: Can PU O-rings be customized?

Yes, size, hardness, cross-section, and color can all be tailored to meet industrial or OEM requirements.

Q3: Are polyurethane O-rings durable?

Yes, they provide excellent wear resistance, elasticity, and chemical stability for long-lasting performance.

Q4: Can PU O-rings replace rubber or metal O-rings?

Yes, polyurethane O-rings often offer superior wear resistance and compression recovery compared with traditional rubber or metal alternatives.

Q5: What industries commonly use PU O-rings?

Industrial machinery, hydraulic and pneumatic systems, automotive, aerospace, and OEM manufacturing.