PU Seal

PU Seal

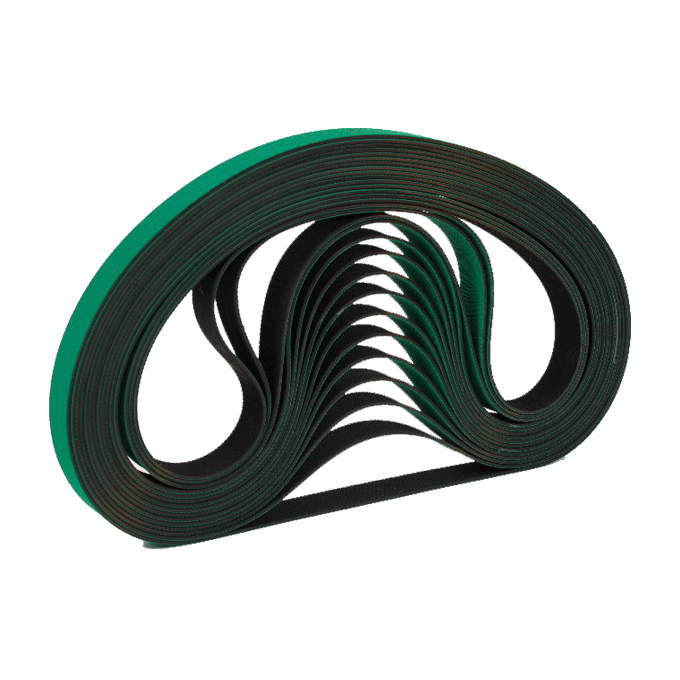

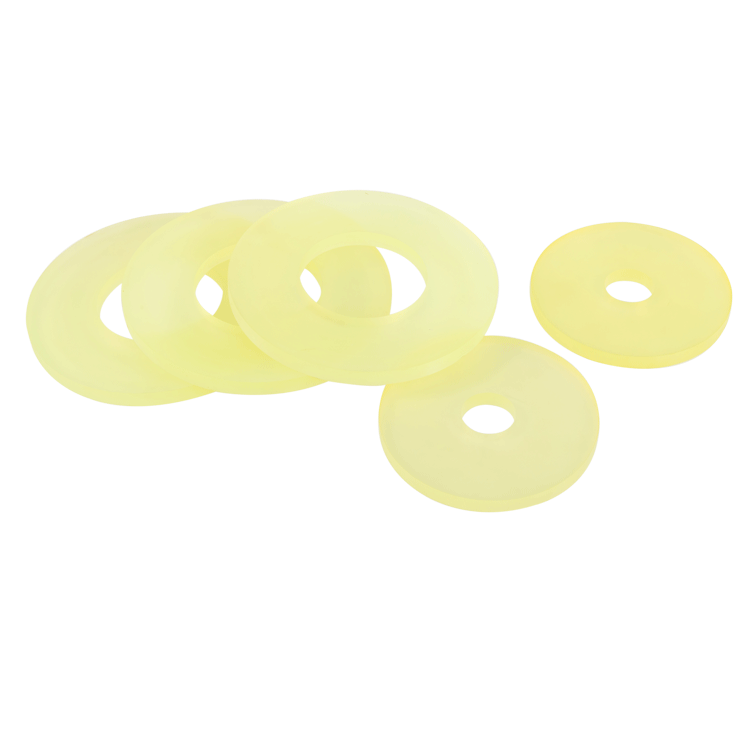

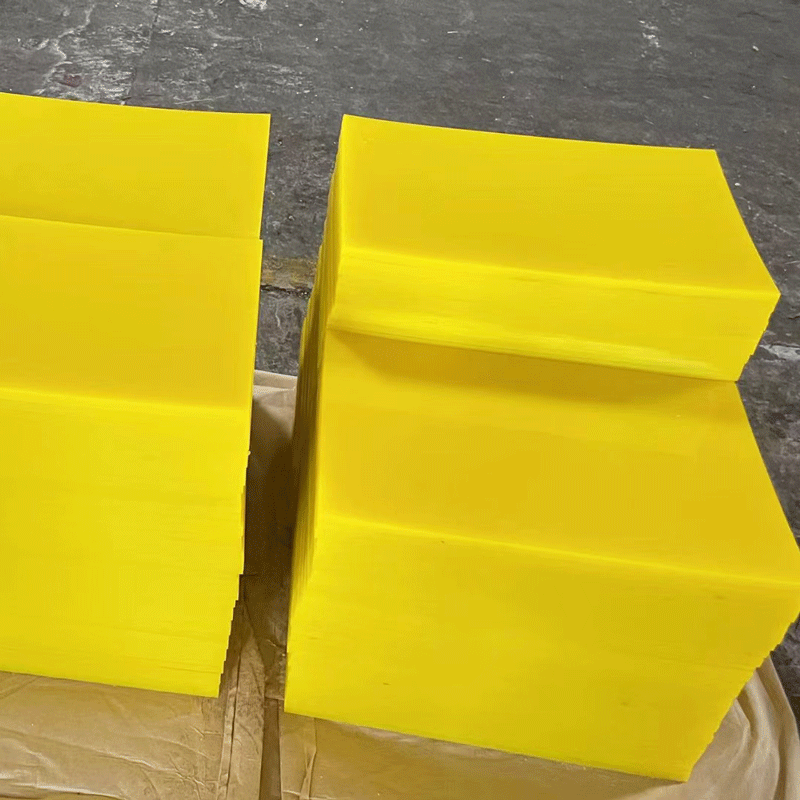

PU seals are high-performance sealing components made from premium polyurethane elastomer, engineered to provide excellent durability, elasticity, and resistance to wear and chemicals. Designed for demanding industrial, hydraulic, and pneumatic applications, PU seals ensure reliable sealing, reduce leakage, and extend the life of machinery and equipment.

Specifications

- Material: High-quality polyurethane (PU) elastomer

- Form: Seal, gasket, O-ring, or custom shape

- Inner Diameter (ID): Customizable

- Outer Diameter (OD): Customizable

- Cross-Section / Thickness: Customizable

- Hardness: Multiple Shore A grades available

- Color Options: Standard or custom

- Resistance: Wear, abrasion, chemical, oil, and impact resistant

- Temperature Range: Suitable for hydraulic, pneumatic, and industrial applications

Key Features & Performance Advantages

- Superior Wear & Abrasion Resistance

Ensures long-lasting sealing performance under continuous use - Excellent Elasticity & Compression Recovery

Maintains tight seals under pressure and mechanical stress - Chemical & Oil Resistant

Performs reliably in hydraulic fluids, oils, and industrial chemicals - Customizable Dimensions & Hardness

Tailored for OEM machinery, hydraulic systems, or industrial equipment - Durable & Long-Lasting

Reduces maintenance frequency and equipment downtime - Easy Replacement & Installation

Compatible with standard or custom machinery components

Typical Applications

- Hydraulic and pneumatic cylinders

- Industrial machinery seals

- Automotive and aerospace applications

- OEM machinery replacement

- Fluid transfer systems and pressurized equipment

- Vibration and leakage prevention in mechanical assemblies

Customization & OEM Support

- Custom inner diameter, outer diameter, cross-section, and hardness

- Color and shape options for OEM applications

- Small-batch and large-scale production available

- Technical support for design and performance optimization

FAQ

Q1: What are PU seals used for?

They are used to provide reliable sealing in hydraulic, pneumatic, and industrial applications to prevent leaks and maintain pressure.

Q2: Can PU seals be customized?

Yes, size, hardness, cross-section, and shape can all be tailored for specific industrial or OEM requirements.

Q3: Are PU seals durable?

Yes, they offer excellent wear resistance, elasticity, and chemical stability for long-term performance.

Q4: Can PU seals replace rubber or metal seals?

Yes, polyurethane seals often outperform rubber or metal in wear resistance, elasticity, and longevity.

Q5: Which industries commonly use PU seals?

Hydraulic and pneumatic systems, industrial machinery, automotive, aerospace, and OEM manufacturing.