V Guide Conveyor Belt

V Guide Conveyor Belt

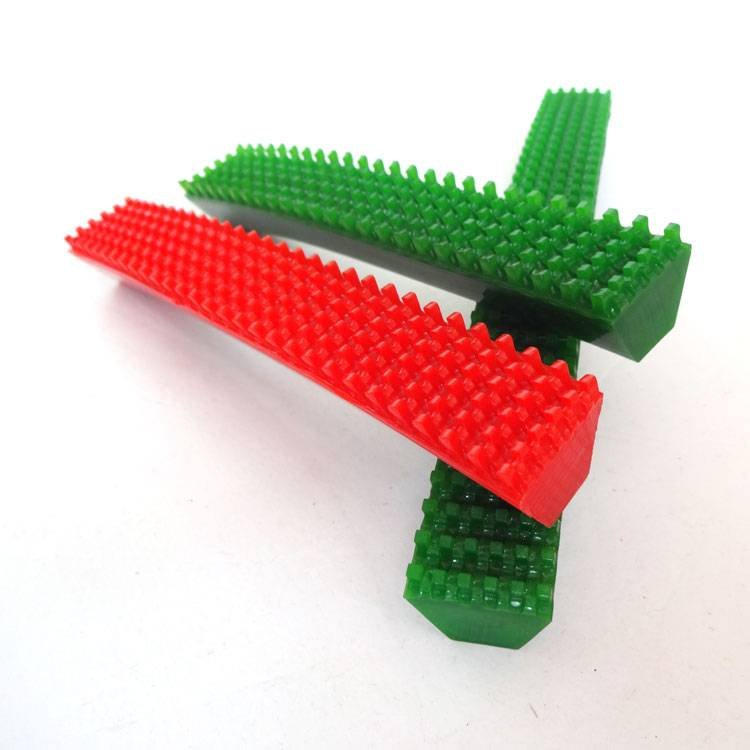

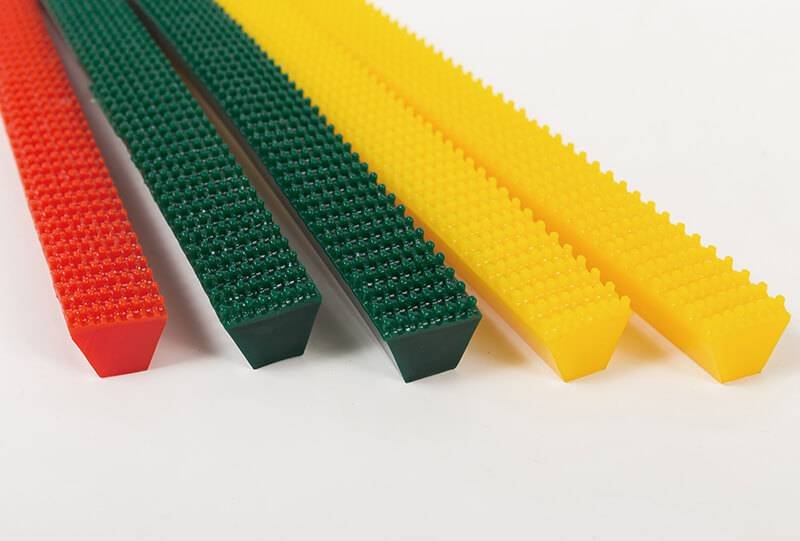

V guide conveyor belts are specialized polyurethane belts designed with integrated V-shaped guides to ensure precise material alignment and stable transportation. These belts prevent lateral movement, reduce spillage, and improve conveyor efficiency in industrial production lines.

Specifications

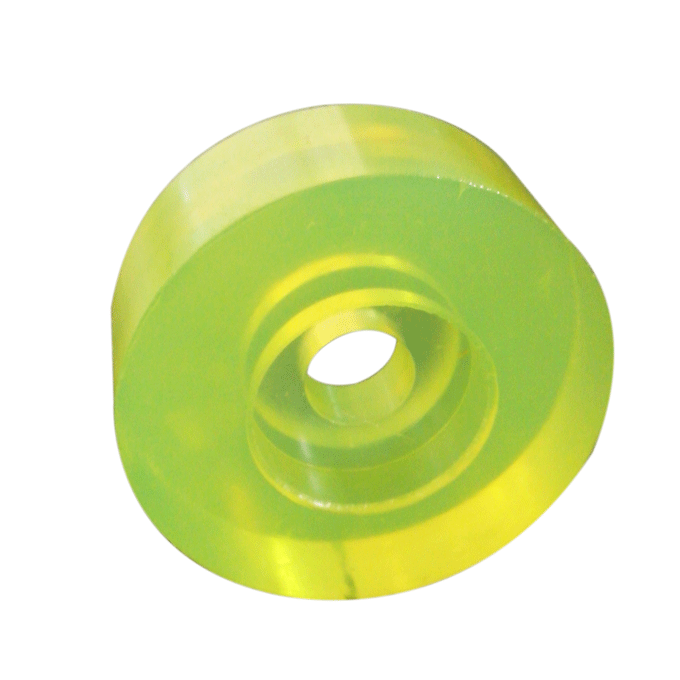

- Material: Thermoplastic Polyurethane (TPU)

- Type: V guide conveyor belt

- Width & Length: Customizable

- Guide Profile: Standard V-guide or custom design

- Thickness: Adjustable based on conveyor load

- Hardness: Shore A options for different industrial needs

- Color: Standard or custom colors

- Temperature Range: Suitable for industrial operating conditions

- Chemical Resistance: Oils, fuels, mild acids, and alkalis

Key Features & Advantages

- V-Shaped Guides for Accurate Material Alignment

Prevents belt misalignment and reduces spillage - High Wear & Tear Resistance

Ensures long-lasting performance in continuous operation - Durable & Impact-Resistant

Withstands heavy loads and high-speed conveyor applications - Customizable Sizes & Guide Profiles

Tailored to fit various conveyor widths and operational requirements - Smooth & Quiet Operation

Optimized for minimal noise and vibration - Chemical & Oil Resistance

Performs reliably in contact with industrial oils and mild chemicals

Typical Applications

- Automated conveyor systems in manufacturing

- Food processing and packaging lines

- Logistics and warehouse material handling

- Mining and bulk material transport

- Electronics assembly and component transport

Customization & OEM Services

- Custom belt lengths, widths, and V-guide profiles

- PU formulations for enhanced wear, chemical, or heat resistance

- Pre-fabricated or ready-to-install conveyor belts

- OEM bulk supply and branding options

FAQ

Q1: What is a V guide conveyor belt?

A V guide conveyor belt is a polyurethane belt with integrated V-shaped guides to ensure precise alignment and prevent lateral belt movement.

Q2: Which industries commonly use V guide conveyor belts?

Packaging, food processing, logistics, mining, and automated manufacturing lines.

Q3: Can these belts be customized?

Yes, length, width, guide profile, and hardness can be tailored to specific conveyor requirements.

Q4: How do V guides improve conveyor performance?

They prevent belt misalignment, reduce spillage, and ensure smooth, consistent material handling.

Q5: Are these belts resistant to chemicals and oils?

Yes, PU V guide belts are designed to maintain performance in contact with industrial oils, fuels, and mild chemicals.