BLOG

Blog

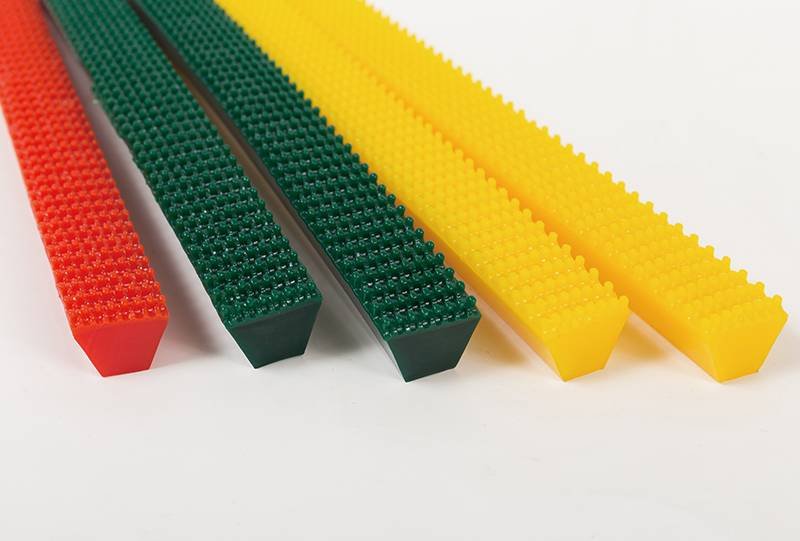

Choosing the right TPU (Thermoplastic Polyurethane) belt for your industry is crucial for ensuring optimal performance, durability, and cost-effectiveness. TPU belts are used across a wide range of industries, from manufacturing and logistics to food processing and medical applications. Each industry has specific requirements based on factors like load capacity, temperature resistance, and flexibility. In … How to Choose the Right TPU Belt for Your Industry Read More » ...

When choosing a conveyor belt for industrial applications, cost-effectiveness is a key factor. While initial investment costs for thermoplastic polyurethane (TPU) belts may be higher than other materials such as PVC or rubber, the long-term benefits of using TPU belts far outweigh the initial price. TPU belts offer excellent durability, efficiency, and low maintenance, resulting … The Cost-Effectiveness of TPU Belts Over Their Lifespan Read More » ...

Thermoplastic Polyurethane (TPU) belts are widely used in various industries due to their durability, flexibility, and resistance to wear and chemicals. However, proper maintenance is essential to ensure their longevity and efficiency. Regular upkeep not only extends the lifespan of TPU belts but also improves conveyor performance, reduces downtime, and lowers operational costs. In this … TPU Belt Maintenance: Best Practices for Longevity and Efficiency Read More » ...

Thermoplastic Polyurethane (TPU) belts have revolutionized various industries with their durability, flexibility, and superior performance. As technology advances, the demand for high-performance conveyor belts continues to grow, driving innovations in TPU belt manufacturing. From sustainability initiatives to smart conveyor systems, the future of TPU belts is shaped by emerging trends that improve efficiency, durability, and … The Future of TPU Belts: Trends and Innovations to Watch Read More » ...

The textile industry relies on high-performance conveyor systems to ensure seamless production processes, from fabric weaving to garment finishing. Thermoplastic Polyurethane (TPU) belts have become a preferred choice due to their efficiency, flexibility, and reliability. Compared to traditional rubber and PVC belts, TPU conveyor belts offer superior wear resistance, smooth operation, and minimal maintenance, making … TPU Belts in the Textile Industry: Efficient, Flexible, and Reliable Read More » ...

Thermoplastic Polyurethane (TPU) has become a leading material choice for conveyor belts in various industries. Its unique combination of durability, flexibility, and chemical resistance makes it superior to traditional materials like PVC and rubber. But what exactly makes TPU so effective? Understanding the science behind TPU reveals why it is the ideal material for modern … The Science Behind TPU: Why It’s the Ideal Material for Conveyor Belts Read More » ...

In the fast-evolving world of packaging automation, efficiency, durability, and hygiene are critical factors that determine the success of a production line. TPU (Thermoplastic Polyurethane) belts have emerged as a game-changing solution, offering superior performance compared to traditional PVC and rubber belts. Their high wear resistance, flexibility, and compliance with food safety standards make TPU … How TPU Belts Are Revolutionizing Packaging Automation Read More » ...

As industries strive for sustainability, the choice of conveyor belt materials plays a significant role in reducing environmental impact. Traditional materials like PVC and rubber have long been used, but they come with drawbacks such as high energy consumption, pollution, and limited recyclability. TPU (Thermoplastic Polyurethane) belts, on the other hand, offer a more eco-friendly … Environmental Impact of TPU Belts: A Greener Option Read More » ...

In industrial and commercial conveyor systems, choosing the right belt material is crucial for efficiency, durability, and cost-effectiveness. Traditionally, PVC belts and rubber belts have been the go-to options for various industries. However, TPU (Thermoplastic Polyurethane) belts are emerging as the superior choice, offering higher durability, flexibility, and hygiene standards. With industries such as food … TPU Belts vs. PVC and Rubber: Why TPU Is the Future Read More » ...

In today’s fast-paced industrial landscape, the demand for customized solutions is growing. TPU (Thermoplastic Polyurethane) belts are no exception, offering a versatile and durable option for industries with specific performance needs. Unlike traditional conveyor belts, custom TPU belts can be tailored to meet the unique challenges faced by various industries, ensuring optimized efficiency, extended lifespan, … Custom TPU Belt Solutions for Specific Industries Read More » ...

In the medical industry, equipment reliability, precision, and performance are critical. Conveyor belts play a vital role in ensuring smooth and efficient operation of various medical devices and equipment. Thermoplastic Polyurethane (TPU) belts have emerged as a top choice in medical applications due to their superior performance, durability, and flexibility. These belts offer exceptional wear … TPU Belts in Medical Equipment: High Precision and Performance Read More » ...

In industrial manufacturing, choosing the right materials for operational processes is essential for ensuring efficiency, durability, and cost-effectiveness. One material that has proven its worth across various industries is TPU (Thermoplastic Polyurethane). TPU belts are increasingly becoming the preferred choice for many industrial applications due to their superior properties, including durability, flexibility, and chemical resistance. … The Advantages of TPU Belts in Industrial Applications Read More » ...

In industrial applications, conveyor systems play a pivotal role in streamlining operations, reducing manual labor, and ensuring the smooth movement of materials. One of the most critical components of these systems is the conveyor belt. Over the years, TPU (Thermoplastic Polyurethane) belts have become a preferred choice for industries seeking enhanced durability, flexibility, and cost-effectiveness. … How TPU Belts Improve Conveyor System Efficiency Read More » ...

The automotive industry is one of the most demanding sectors when it comes to precision, durability, and efficiency. Conveyor systems, assembly lines, and various machinery must perform seamlessly to meet production goals and ensure high-quality vehicle manufacturing. One material that has proven to be indispensable in these processes is TPU (Thermoplastic Polyurethane). TPU belts offer … The Role of TPU Belts in the Automotive Industry Read More » ...

The food and beverage industry operates under stringent standards to ensure hygiene, safety, and efficiency at every stage of production. From raw material handling to packaging, conveyor belts are an essential component of these processes. TPU (Thermoplastic Polyurethane) belts have become a popular choice in this sector, offering a cleaner, safer, and more durable alternative … TPU Belts in Food and Beverage Industries: A Cleaner, Safer Choice Read More » ...

As industries strive for more sustainable practices, the recycling of polyurethane (PU) has become essential in promoting a circular economy. Polyurethane is used extensively in products ranging from flexible foams to rigid coatings and adhesives. However, with millions of tons of PU products discarded annually, finding ways to recycle and repurpose this versatile material is … Polyurethane Recycling: Closing the Loop in Sustainable Manufacturing Read More » ...