Blog

In modern industrial manufacturing, transmission efficiency, equipment stability, and service life directly affect production costs and business competitiveness. As the demand for high-performance transmission materials continues to grow, the polyurethane drive belt has become a preferred upgrade from traditional rubber belts. Compared with rubber materials, polyurethane offers superior wear resistance, tensile strength, elasticity, and overall … What Is a Polyurethane Drive Belt and Why It Outperforms Rubber Belts Read More » ...

Wheel polyurethane is quickly becoming the material of choice for various industries, offering unmatched durability, flexibility, and wear resistance. However, to fully capitalize on the benefits of polyurethane wheel, businesses must often turn to custom solutions to meet the specific demands of their operations. Whether you’re in automotive, logistics, or food processing, wheel polyurethane customization … Wheel Polyurethane Customization: Tailoring Solutions for Specific Industry Needs Read More » ...

Choosing the right polyurethane rod supplier is a crucial decision for businesses across various industries. Polyurethane rods are known for their outstanding durability, flexibility, and resistance to wear, making them ideal for use in manufacturing, automotive, ceramics, and many other sectors. However, selecting a supplier who can consistently provide high-quality, reliable products that meet your … Polyurethane Rod Supplier: How to Choose the Right One for Your Industrial Needs Read More » ...

In modern industrial and logistics operations, the choice of equipment components can significantly impact efficiency, safety, and maintenance costs. Among these components, polyurethane wheels have emerged as a preferred solution for a wide range of applications. Their unique combination of durability, flexibility, and chemical resistance makes them ideal for environments where traditional rubber or metal … Polyurethane Wheels: Key Features and Advantages for Industrial Use Read More » ...

When considering materials for industrial, automotive, or engineering projects, one question often arises: what is thermoplastic polyurethane (TPU) and why is it so widely used? TPU is a versatile polymer that combines the processing ease of plastics with the elasticity of rubber. Its unique properties make it ideal for applications requiring durability, flexibility, and chemical … What is Thermoplastic Polyurethane and How to Choose the Right Type for Your Project Read More » ...

Polyurethane tubing, also known as PU tubing or PUR tubing, is one of the most versatile flexible tubing materials used across pneumatic systems, automation equipment, robotics, medical devices, and industrial machinery. Engineers choose polyurethane tubing for its excellent flexibility, high abrasion resistance, strong tensile strength, and reliable pressure performance. However, selecting the right type and … Common Issues with Polyurethane Tubing and How to Solve Them Read More » ...

In modern industrial and manufacturing applications, polyurethane sheeting plays a crucial role in providing durability, impact resistance, and flexibility for a wide range of components. Choosing the right polyurethane sheet is essential, as the material’s thickness, hardness, and chemical resistance directly impact the performance and lifespan of equipment. Selecting the ideal PU sheeting ensures reliable … How to Choose the Right Polyurethane Sheeting for Your Project Read More » ...

Polyurethane materials have become an essential part of modern manufacturing, widely used in industries ranging from construction and automotive to ceramics and sports equipment. Among the many variations of polyurethane, thermoplastic polyurethane (TPU) stands out as one of the most versatile and high-performance options. But how does TPU compare to other PU materials? And more … Thermoplastic Polyurethane vs Other PU Materials: Which One Should You Choose? Read More » ...

In industries where equipment is subjected to constant abrasion, impact, and friction, material durability is non-negotiable. This is where polyurethane rubber sheets outperform traditional materials like natural rubber, nitrile, and even some metals. At PENGDE NEW MATERIAL TECHNOLOGY CO., LTD, we specialize in the production of premium polyurethane rubber sheets engineered to withstand demanding environments. … Why Polyurethane Rubber Sheets Are Ideal for High-Wear Applications Read More » ...

Choosing the right polyurethane sheet is essential for achieving optimal performance in industrial applications. With its superior wear resistance, load-bearing capacity, and chemical resilience, polyurethane (PU) is a preferred material across industries such as mining, construction, logistics, automotive, and manufacturing. However, not all polyurethane sheets are created equal. At PENGDE PU, we specialize in manufacturing … How to Select the Right Polyurethane Sheet for Industrial Use Read More » ...

Selecting the appropriate material for industrial or commercial use is critical to product performance, longevity, and cost-efficiency. Among elastomeric materials, polyurethane sheets and rubber sheets are two of the most widely used. While both are flexible and durable, they differ significantly in their mechanical and chemical properties. In general, polyurethane sheets are better for high-wear … Polyurethane vs. Rubber Sheets: Which Material Should You Choose? Read More » ...

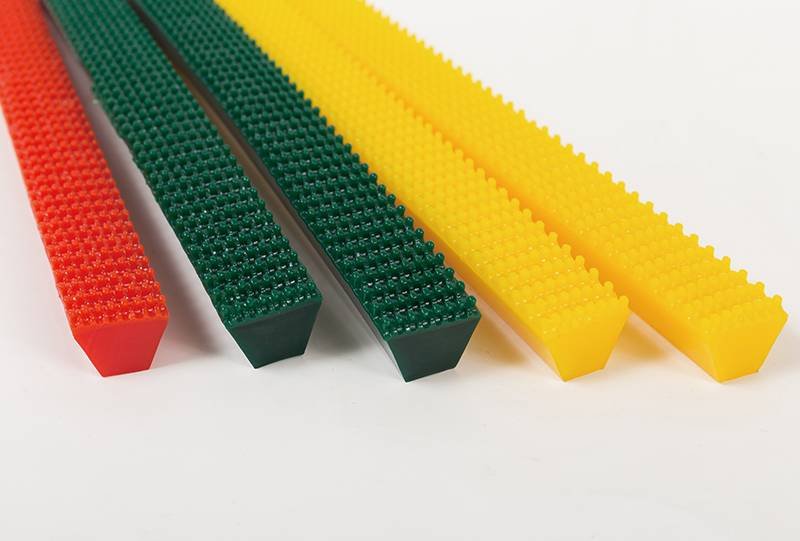

Choosing the right TPU (Thermoplastic Polyurethane) belt for your industry is crucial for ensuring optimal performance, durability, and cost-effectiveness. TPU belts are used across a wide range of industries, from manufacturing and logistics to food processing and medical applications. Each industry has specific requirements based on factors like load capacity, temperature resistance, and flexibility. In … How to Choose the Right TPU Belt for Your Industry Read More » ...

When choosing a conveyor belt for industrial applications, cost-effectiveness is a key factor. While initial investment costs for thermoplastic polyurethane (TPU) belts may be higher than other materials such as PVC or rubber, the long-term benefits of using TPU belts far outweigh the initial price. TPU belts offer excellent durability, efficiency, and low maintenance, resulting … The Cost-Effectiveness of TPU Belts Over Their Lifespan Read More » ...

Thermoplastic Polyurethane (TPU) belts are widely used in various industries due to their durability, flexibility, and resistance to wear and chemicals. However, proper maintenance is essential to ensure their longevity and efficiency. Regular upkeep not only extends the lifespan of TPU belts but also improves conveyor performance, reduces downtime, and lowers operational costs. In this … TPU Belt Maintenance: Best Practices for Longevity and Efficiency Read More » ...

In the fast-evolving world of packaging automation, efficiency, durability, and hygiene are critical factors that determine the success of a production line. TPU (Thermoplastic Polyurethane) belts have emerged as a game-changing solution, offering superior performance compared to traditional PVC and rubber belts. Their high wear resistance, flexibility, and compliance with food safety standards make TPU … How TPU Belts Are Revolutionizing Packaging Automation Read More » ...

As industries strive for sustainability, the choice of conveyor belt materials plays a significant role in reducing environmental impact. Traditional materials like PVC and rubber have long been used, but they come with drawbacks such as high energy consumption, pollution, and limited recyclability. TPU (Thermoplastic Polyurethane) belts, on the other hand, offer a more eco-friendly … Environmental Impact of TPU Belts: A Greener Option Read More » ...